Balanced hoisting mechanism for hoisting heavy piece

A technology for hoisting and heavy parts, which is applied in the directions of transportation and packaging, load hoisting components, etc., can solve problems such as uneven force on the lifting point, and achieve the effect of simple structure, strong adaptability and solving uneven force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

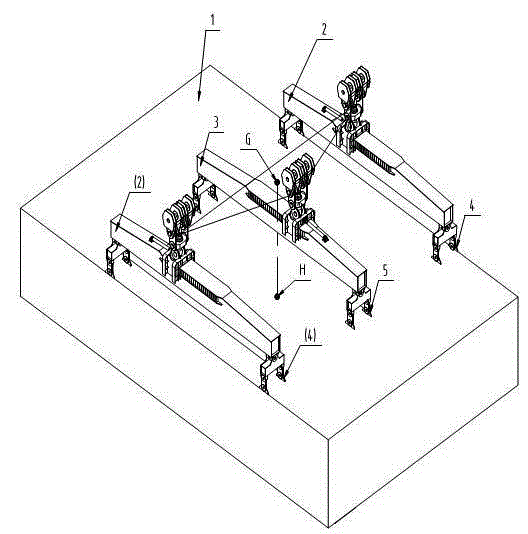

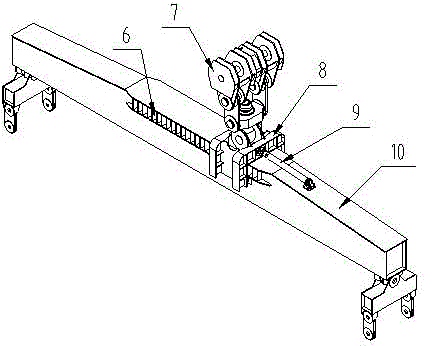

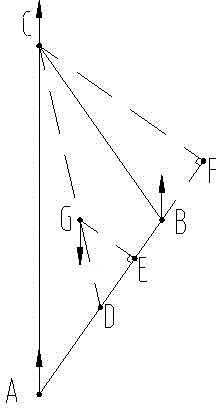

[0015] The device includes two side spreaders 2 and a middle spreader 3, and each side spreader 2 and middle spreader 3 include a hook 7, a lifting point slider 8, a spreader distribution beam 10, A spreader oil cylinder 9, the hook 7 is installed on the lifting point slider 8, the lifting point slider 8 is placed on the guide rail 6 of the spreader distribution beam 10, one end of the spreader oil cylinder 9 is installed on the lifting point slider 8, and the other end Fixed on the spreader distribution beam 10, when the spreader oil cylinder 9 stretches, the lifting point slider 8 can slide back and forth along the guide rail 6 of the spreader distribution beam 10, thereby realizing the adjustment of the position of the hook 7, such as figure 1 , figure 2 shown.

[0016] The two side spreaders 2 are connected to the heavy part 1 through the side lifting lugs 4, and the middle spreader 3 is connected to the heavy part 1 through the middle lifting lugs 5, and each hook 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com