Six-freedom degree three-dimensional printing equipment

A 3D printing, degree of freedom technology, applied in the direction of additive processing, etc., can solve problems such as low printing efficiency, easy collapse of suspended structures, and defects in structural design, and achieve the effect of improving strength, improving printing process, and simple and convenient debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] The invention is mainly composed of a body system, a drive system, a transmission system and a display system.

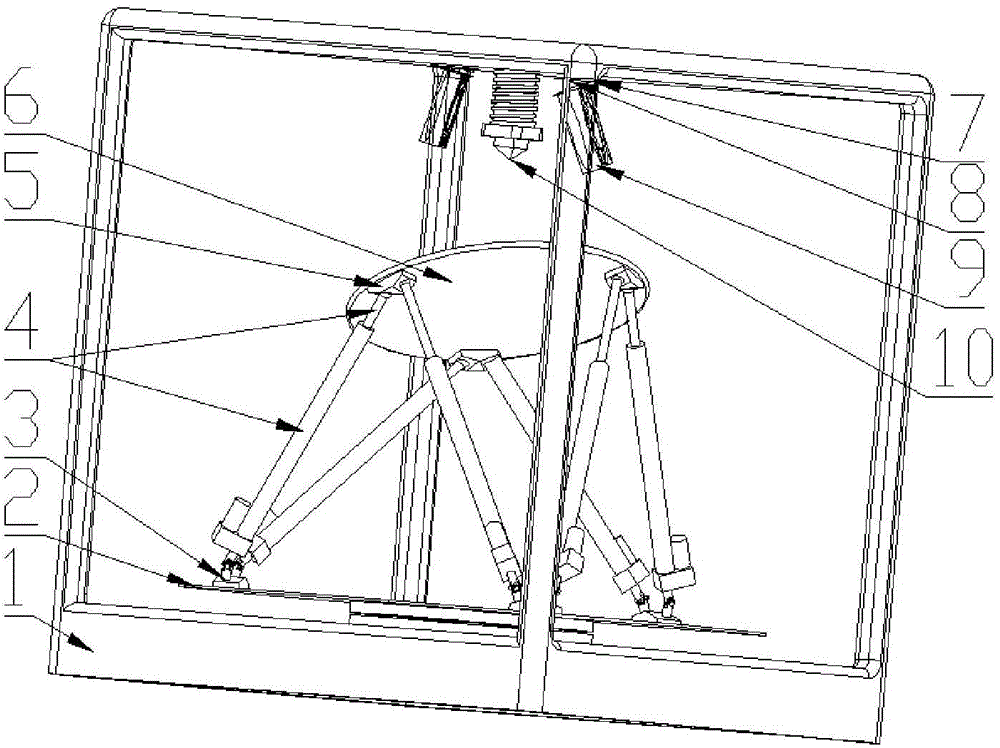

[0020] Such as figure 1 As shown, 1) The frame is a rectangular parallelepiped with a hollow in the middle; (1) The frame is embedded with plexiglass on all sides to ensure a good viewing angle; Headers and (7) v-plates. (8) The screws are screwed into the (1) frame to fix the (7) v-shaped plate, and the (9) fan is fixed on the (7) v-shaped plate, which can ensure that the (9) fan and (10) extrusion head are integrated 30° inclination. (10) The end of the extrusion head has an external thread, and the middle part is a spiral structure made of aluminum to ensure a good heat dissipation effect. (1) There is an internal thread in the middle of the top of the frame, and the (10) extrusion head can be screwed into the (1) frame to fix it.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com