Mew method for increasing laser boring depth of stainless steel

A laser drilling, stainless steel technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of low photoelectric conversion efficiency, low laser processing efficiency, huge power consumption, etc., to achieve less energy consumption, processing High efficiency and the effect of increasing the drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A new method to increase the depth of stainless steel laser drilling, including the following steps:

[0038] (1) Stainless steel pretreatment: grinding, polishing, ultrasonic cleaning and drying treatment on the surface of 304 stainless steel;

[0039] (2) Preparation of gold nanoparticles: add 1.7ml of 0.01g / ml chloroauric acid aqueous solution to 50ml of water, use oil bath method to heat to boiling and keep for 10min, then add 38.8mmol / L sodium citrate 2.25ml, Heating and stirring at a speed of 10 r / s for 15 min, to obtain the gold nanoparticle solution with a particle diameter of 40 nm and an absorption wavelength of 532 nm.

[0040] (3) Self-assembly of gold nanoparticles on the surface of stainless steel: Use a pipette to take 2.0ml of 97% 3-aminopropyltrimethoxysilane (APTMS) solution and dissolve it in 50ml of methanol to configure it as APTMS- Methanol solution: The stainless steel treated in step (1) is soaked in the APTMS-methanol solution for 12 hours and then ta...

Embodiment 2

[0048] Step (1) to step (3) are the same as in Example 1,

[0049] Step (4) Laser drilling: laser drilling is performed on the surface of the self-assembled stainless steel in step (3), and the wavelength parameter of the laser is the same as the absorption wavelength of the gold nanoparticles; other laser parameters are set to the laser frequency of 1KHz , Wavelength 532nm, pulse width 500ms, laser energy 80uJ, and 5 pulses.

[0050] (5) Stainless steel post-treatment: The stainless steel surface with holes is washed twice in an ultrasonic cleaner with alcohol and acetone alternately on the surface of the stainless steel after step (4), and dried to obtain the stainless steel with holes.

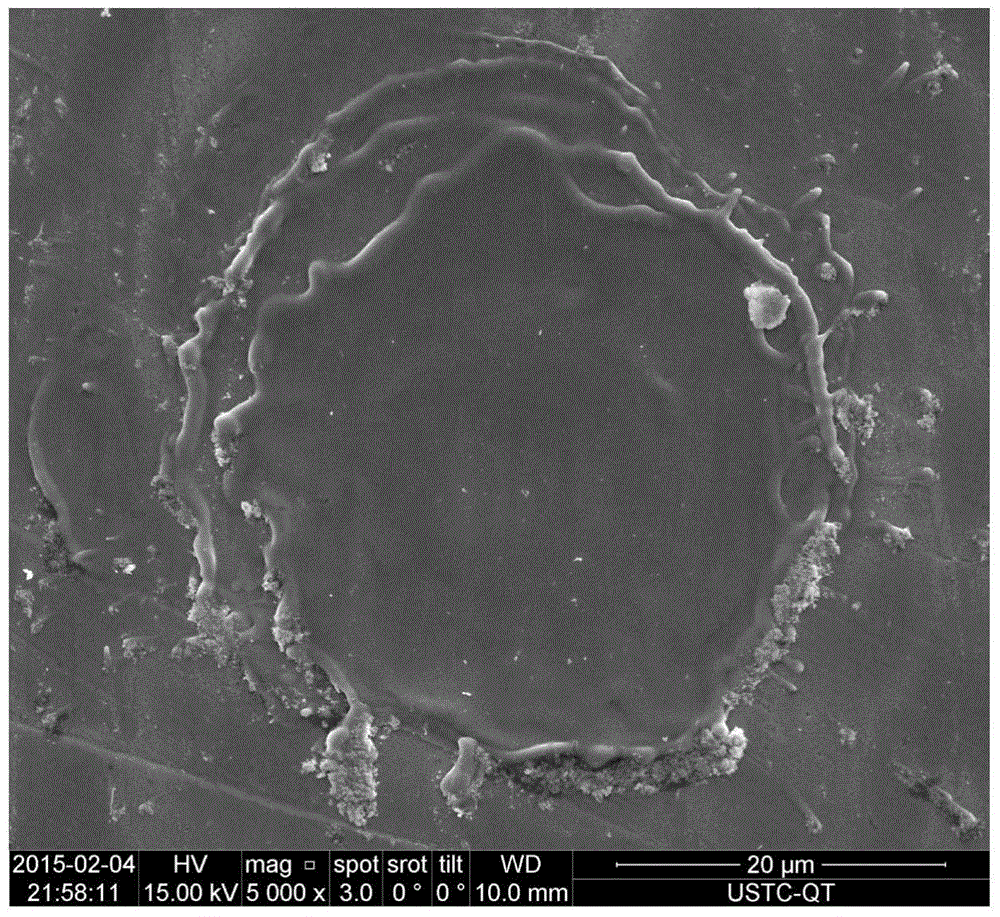

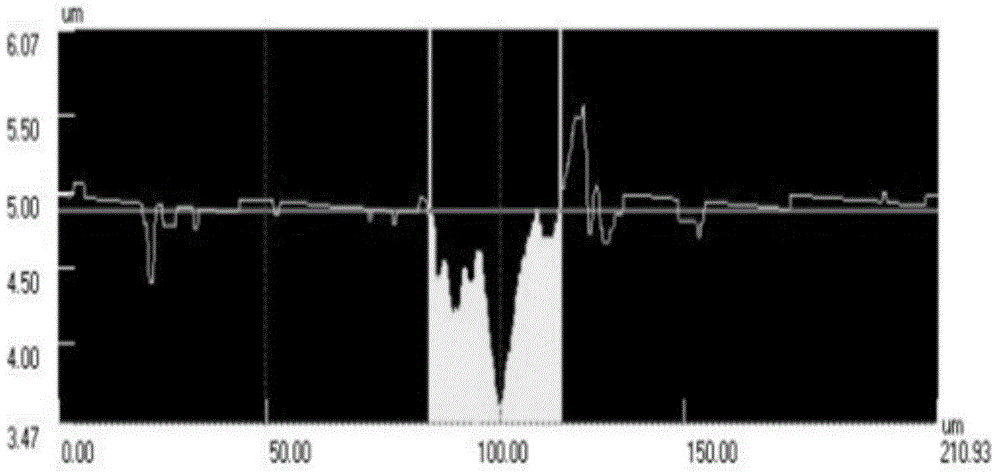

[0051] We analyze the morphology and depth of the holes obtained in Example 2, as Figure 5 As shown, the pits have an obvious tapered structure with multiple recast layers. We further measured the hole depth, such as Image 6 As shown, the depth of the hole is 4.45 μm.

Embodiment 3

[0056] Step (1) to step (3) are the same as in Example 1,

[0057] Step (4) Laser drilling: laser drilling is performed on the surface of the self-assembled stainless steel described in step (3), and the wavelength parameter of the laser is the same as the absorption wavelength of the gold nanoparticles; other laser parameters are set to laser frequency 1KHz , Wavelength 532nm, pulse width 500ms, laser energy 120uJ, pulse number 1.

[0058] (5) Stainless steel post-treatment: The stainless steel surface with holes is washed twice in an ultrasonic cleaner with alcohol and acetone alternately on the surface of the stainless steel after step (4), and dried to obtain the stainless steel with holes.

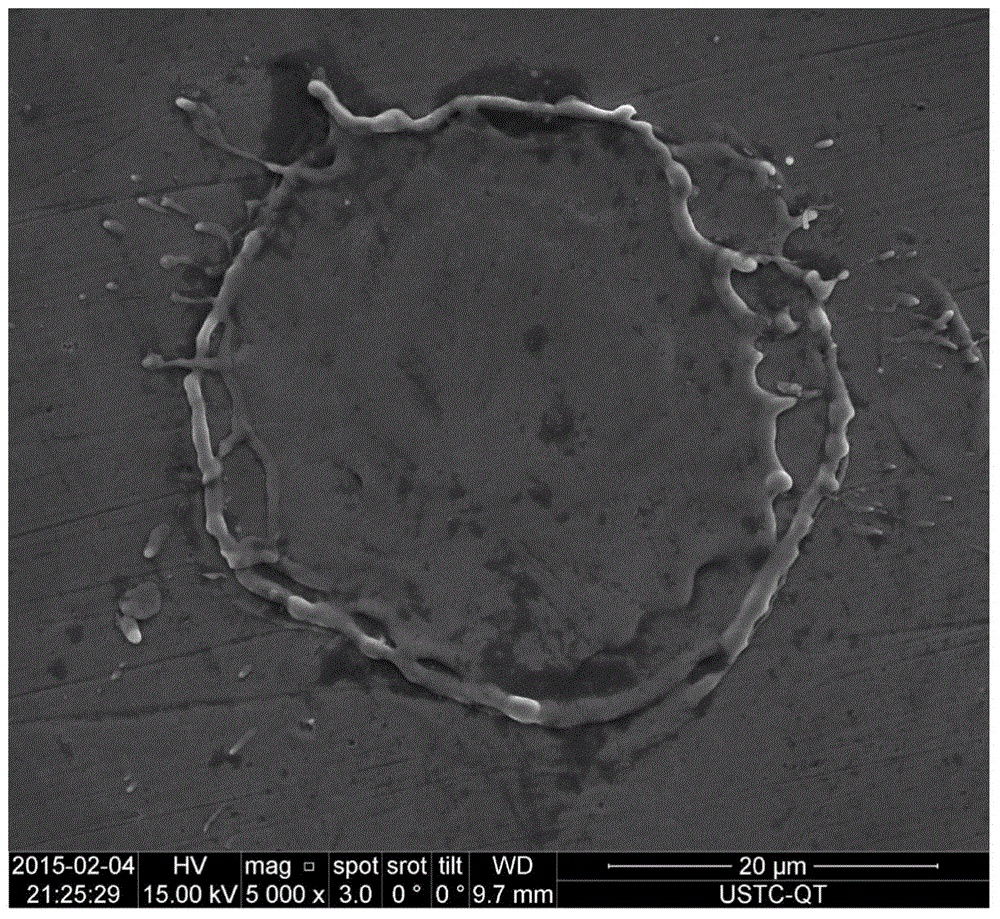

[0059] We analyze the morphology and depth of the holes obtained in Example 2, as Picture 9 As shown, the pit has an incomplete cone structure with a recast layer around it. We further measured the hole depth, such as Picture 10 As shown, the depth of the hole is 1.62 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com