Handheld coiled round wire material head straightening machine

A hand-held, straightening machine technology, applied in the field of straightening machines, can solve the problems of high labor intensity and low efficiency, and achieve the effects of low cost, simple maintenance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

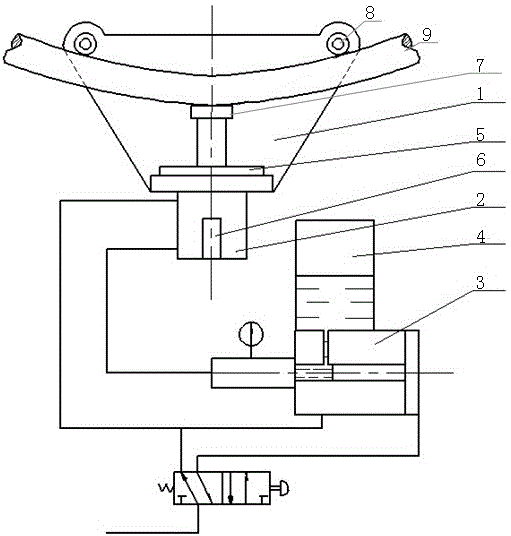

[0011] like figure 1 As shown in the figure, the hand-held round wire material head straightening machine includes a frame 1 and a gas-liquid supercharger. Front handle 5 and rear handle 6 are respectively arranged at both ends of the handle, and a button-type mechanical valve is arranged on the rear handle 6; the booster cylinder 2 in the gas-hydraulic booster is connected with the frame 1 by bolts, and the piston in the booster cylinder 2 The rod is connected with the movable head 7, and two supporting heads 8 are fixed on the frame 1; the supporting head 8 is composed of a supporting shaft and a straightening roller, the supporting shaft is fixed on the frame, and the straightening roller is sleeved on the supporting shaft, The supporting surface of the straightening roller is provided with a positioning groove; the movable head 7 is threadedly connected on the piston rod of the pressurized oil cylinder 2, and the supporting surface of the movable head 7 is provided with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com