Defective material throwing device of automatic screen assembling machine

An assembly machine and poor technology, applied in nonlinear optics, optics, instruments, etc., can solve the problems of low assembly consistency and precision, difficult to meet large-scale production, and labor-intensive employees, and achieve a compact and consistent mechanism structure. Good sex and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

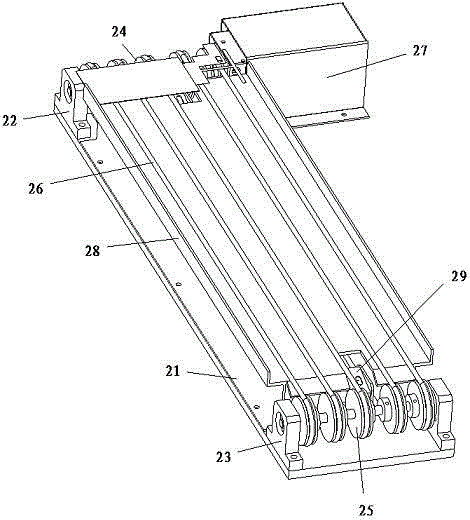

[0008] Such as figure 1 As shown, the present invention discloses a defective throwing device of an automatic screen assembly machine. The defective throwing device includes a defective throwing fixing plate 21 fixed to the chassis table, and defective throwing fixing plates 21 are installed with defective The active fixed seat 22 of throwing material and the passive fixed seat 23 of bad throwing material, the active fixed seat 22 of bad throwing material and the driven fixed seat 23 of bad throwing material are equipped with bad throwing material driving wheel group 24 and bad throwing material driven wheel group 25 , bad material throwing type belt 26 is set between bad throwing material driving wheel set 24 and bad throwing material driven wheel set 25, bad throwing material drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com