Glue liquid circulation system used for honeycomb glue coating process

A technology of circulation system and glue solution, which is applied in the direction of surface coating liquid device, coating, mixer with rotating stirring device, etc., which can solve the problem of not being able to meet the production requirements of aramid paper glued strips and inconvenient to implement , glue unevenness and other problems, to achieve the effect of satisfying the glue viscosity and uniform controllability, reducing cleaning work, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

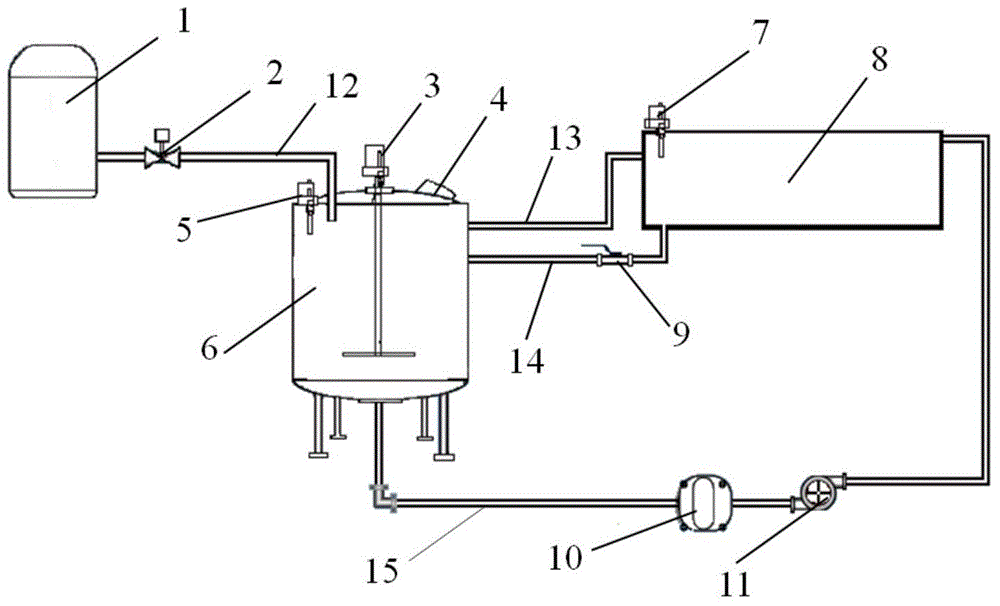

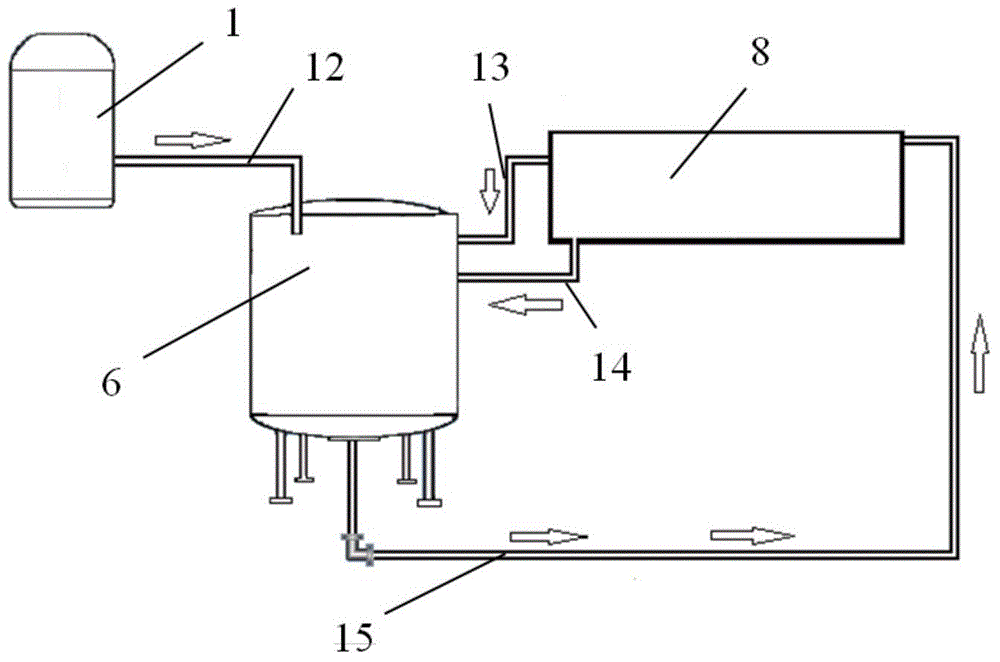

[0011] A detailed description of one embodiment of the invention is provided by way of example only and with reference to the following figures, which are simplified schematic diagrams illustrating the basic structure of the embodiment only.

[0012] Depend on figure 1 and figure 2 It can be seen that the glue circulation equipment in the honeycomb gluing process is composed of a solvent tank 1 , a mixing tank 6 , a gluing tank 8 , a pneumatic diaphragm pump 11 , and a viscosity sensor 10 . The solvent barrel 1 and the mixing barrel 6 are connected through a pipeline 12, and a solvent valve 2 is installed on the pipeline. When the viscosity value is greater than the set value, the cycle control PLC will open the solvent valve 2, and the solvent will enter the mixing barrel, and the viscosity will decrease; When the viscosity value is less than the set value, the circulation control PLC will close the solvent valve 2.

[0013] The pneumatic stirring paddle 3, the original ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com