Method for preparing stepped Pt-Au core-shell structural catalyst

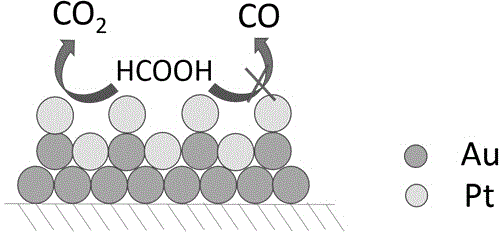

A core-shell structure and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, structural parts, etc., can solve problems such as difficult shell metal single-layer coverage, high utilization rate of precious metals, cumbersome preparation process, etc., to achieve The effect of reducing the generation of toxic intermediate products, improving electrochemical activity and stability, and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

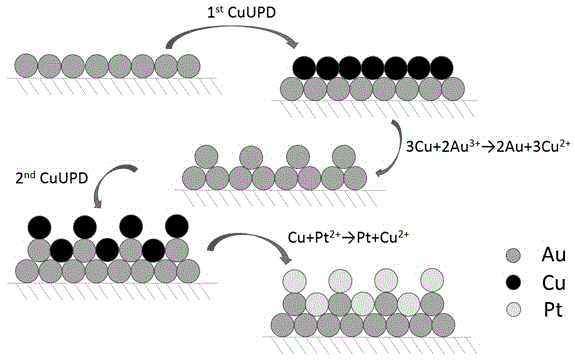

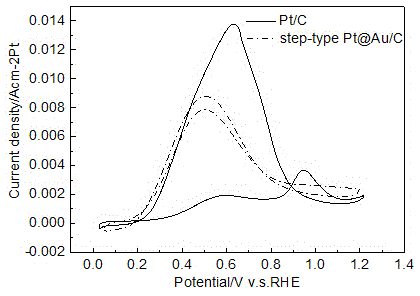

[0044] The invention provides a method for preparing a stepped Pt-Au core-shell structure anode catalyst for a direct formic acid fuel cell, and the specific implementation steps are as follows:

[0045] 1. Preparation of Au / C catalyst:

[0046] The preparation of Au / C is by impregnation reduction method, and the specific steps are as follows:

[0047] (1) Preliminary preparation: ultrasonically disperse 40mg of XC-72R carbon black in ultrapure water for 30min; weigh 19.22mg of sodium borohydride and dissolve it in 0.508mL, 0.1mol / L sodium citrate ice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com