Turntable device

A technology of turntable and round table, which is applied in the field of turntable devices, can solve the problems such as the conduction mechanism hindering the stability of the turntable part and the ground part of the same potential and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

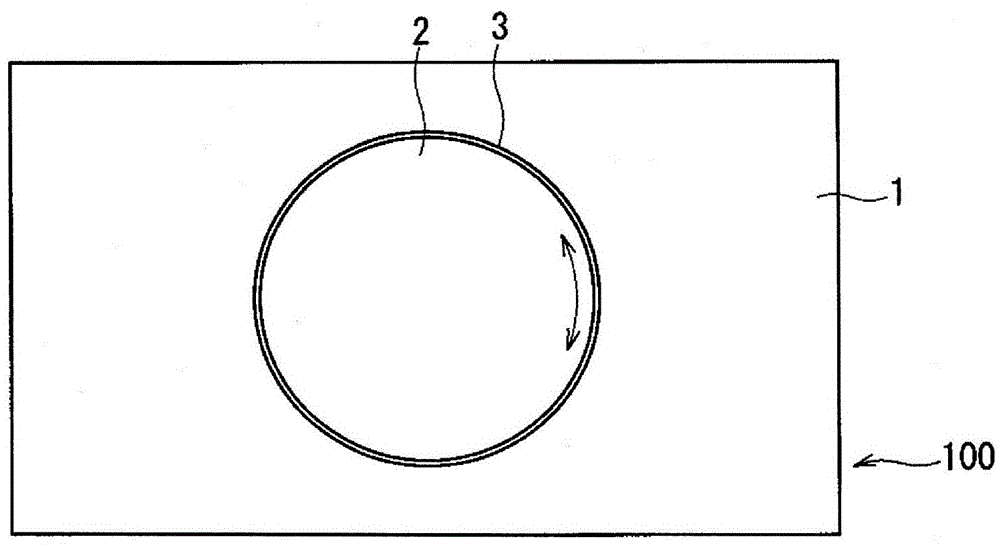

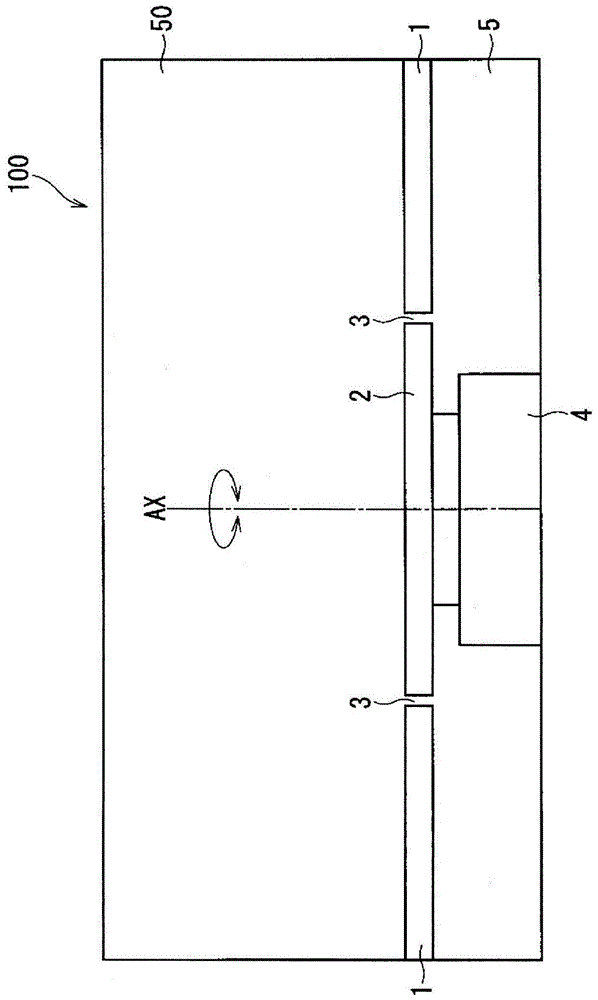

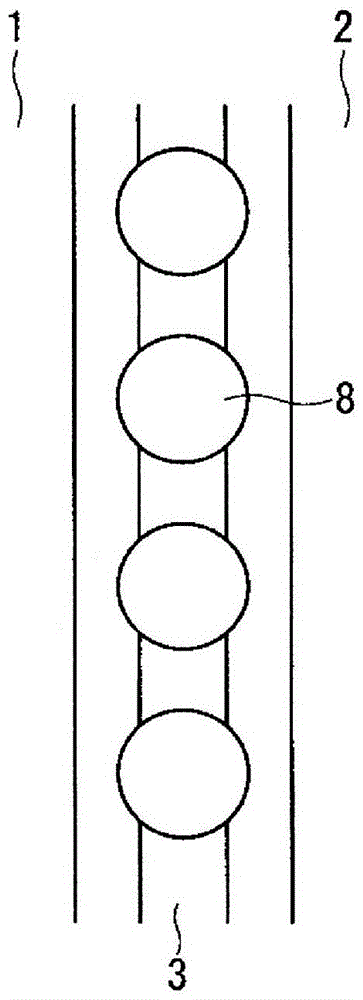

[0041] image 3 It is a plan view showing the structure of the conduction mechanism included in the turntable device according to the present embodiment. also, Figure 4 is a cross-sectional view showing the structure of the conduction mechanism. here, image 3 , 4 is shown in figure 1 , 2 An enlarged view of a part of the gap 3 is shown, including the surrounding structure of the part.

[0042] Such as image 3 , 4As shown, a conductor 8 is arranged as a conduction mechanism. Conductor 8 is arranged so as to be in contact with both floor portion 1 and turntable portion 2 . Furthermore, when the turntable part 2 rotates, the conductor 8 rolls with respect to the floor part 1, maintaining the said contact, and also rolls with respect to the turntable part 2. As shown in FIG. That is, the conductor 8 is not fixed anywhere, but can freely roll in the gap 3 . The specific structure of this embodiment is as follows.

[0043] In the present embodiment, the floor portion ...

Embodiment approach 2

[0065] Figure 6 It is a sectional view showing the structure of the conduction mechanism included in the turntable device according to the present embodiment. here, Figure 6 is shown figure 1 , 2 An enlarged view of a part of the gap 3 is shown, including the surrounding structure of the part.

[0066] Such as Figure 6 As shown, a conductor 8 is arranged as a conduction mechanism. This conductor 8 is arranged so as to be in contact with both the floor portion 1 and the turntable portion 2 . Furthermore, when the turntable part 2 rotates, the conductor 8 rolls with respect to the floor part 1, maintaining the said contact, and also rolls with respect to the turntable part 2. As shown in FIG. That is, the conductor 8 is not fixed anywhere, but can freely roll within the gap 3 (more specifically, within the conductor mounting portion 12 described later). The specific structure of this embodiment is as follows.

[0067] In this embodiment, the floor part 1 is comprised ...

Embodiment approach 3

[0098] In this embodiment, the eaves portion 15 is added to the turntable device according to the second embodiment. Figure 7 It is a sectional view showing the structure of the conduction mechanism included in the turntable device according to the present embodiment. here, Figure 7 is shown figure 1 , 2 An enlarged view of a part of the gap 3 is shown, including the surrounding structure of the part.

[0099] Compare Figure 6 and Figure 7 It can be seen that the eaves portion 15 is additionally provided in the turntable device according to the present embodiment. Such as Figure 7 As shown, the eaves portion 15 covers the conductor mounting portion 12 from above. In addition, the eaves portion 15 is made of, for example, a non-conductive resin or the like.

[0100] here, in Figure 7 In the structural example of , the eaves portion 15 is connected to the ground portion 1 side, but not to the turntable portion 2 side. Additionally, with Figure 7 The structure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com