Cap for cosmetic case

A technology for cosmetic containers and injection ports, which is applied to cosmetic powder containers, packaging cosmetics, and toiletry containers. It can solve the problems of difficult-to-seal sealing force, difficult to provide sealing force, and damage to the crimping surface to achieve stable sealing force. , Prevent damage or damage, strong and stable sealing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

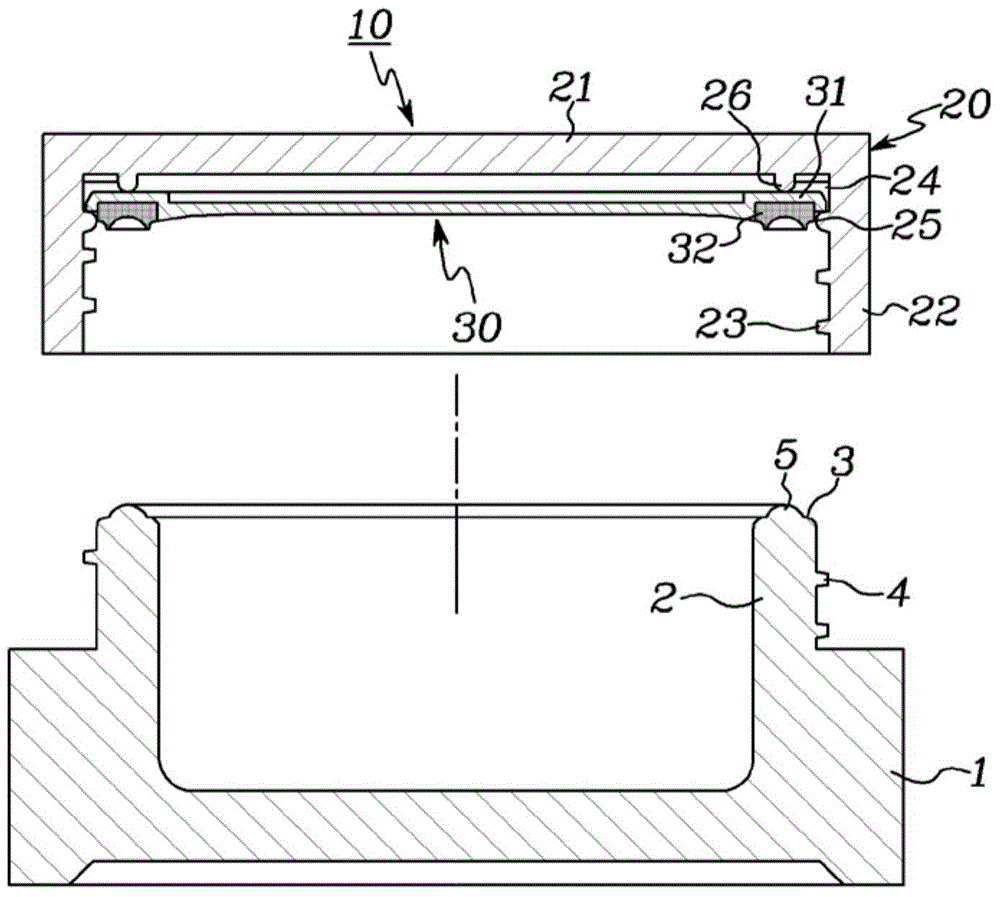

[0033] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

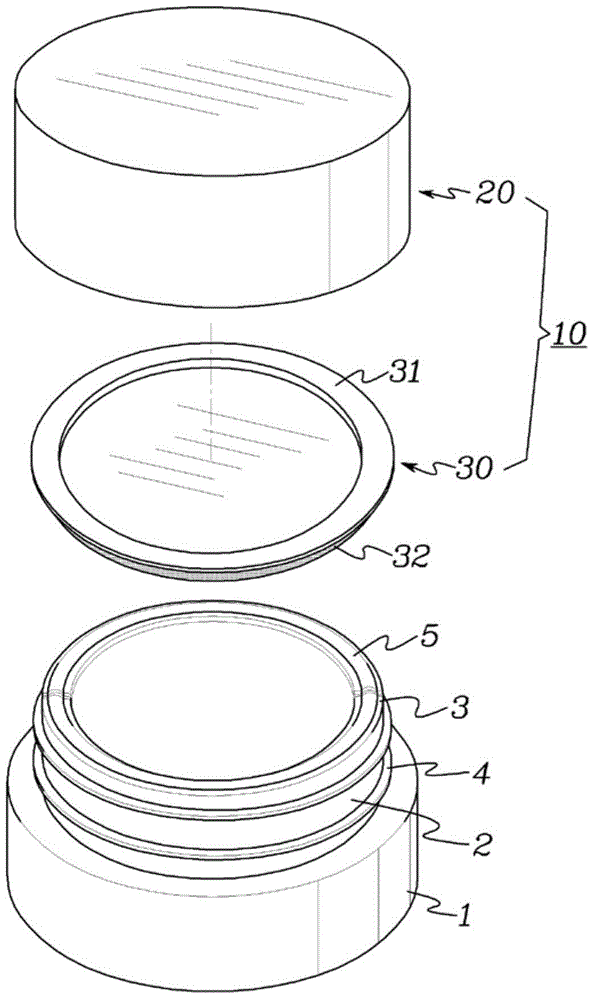

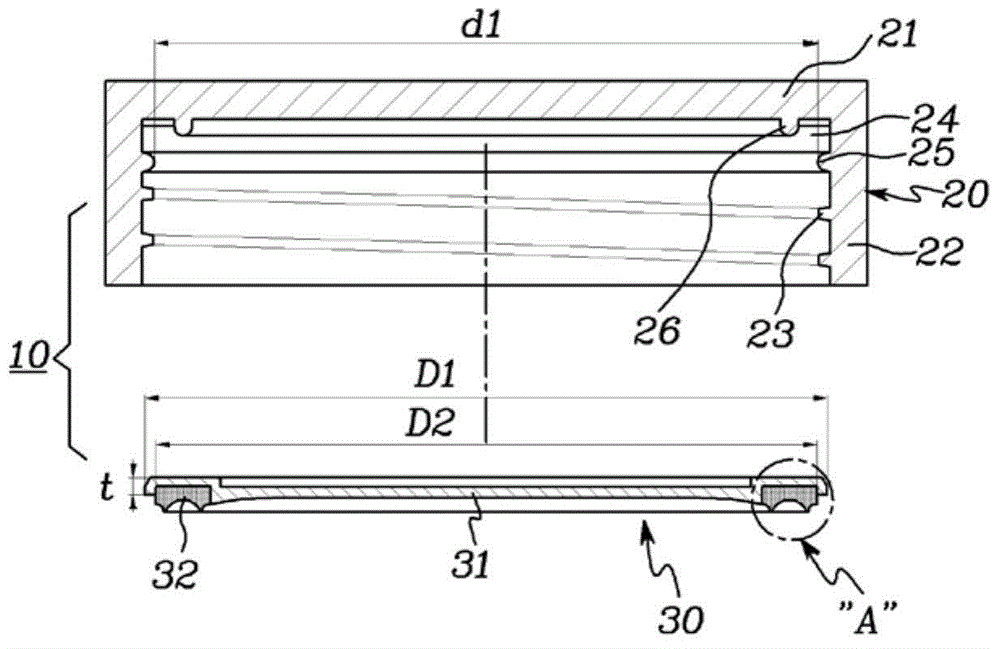

[0034] see Figure 1 to Figure 3 , the cosmetic container cap 10 of the present invention comprises:

[0035] The cover body 20 is made of a hard material, and consists of an upper wall 21, a side wall 22 extending to the lower end of the edge of the upper wall, a threaded portion 23 formed on the inner peripheral surface of the side wall, and an inner wall of the side wall. The surrounding surface forms a sill 25 in order to form the inserting space 24;

[0036] The sealing member 30 can be movably clamped into the insertion space of the above-mentioned cover body. When the above-mentioned cover body performs the opening and closing operation on the injection port of the cosmetic container in a threaded manner, it can provide a sealing force for the injection port 2 of the above-mentioned cosmetic container 1 or remove it;

[0037] The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com