Interlocked high voltage generating circuit and static elimination system using the interlocked high voltage generating circuit

A technology of high-voltage generation and high-voltage power supply, which is applied in the direction of static electricity and electrical components, can solve the problems of low static electricity elimination efficiency, affecting the cleanliness of the clean room, and short flight distance, so as to improve the efficiency of static electricity elimination, improve the efficiency of static electricity removal, The effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

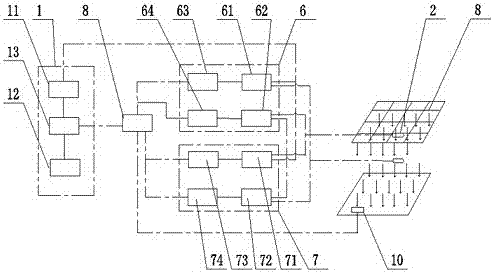

[0045] The invention discloses an indoor static elimination system, as attached image 3 As shown, it includes a number of FFU air outlets 9 arranged on the indoor roof and a number of static state monitors 10, and also includes at least one interlocking high-voltage generating circuit, which is mainly used to selectively generate a For symmetrical electrodes, symmetrical discharge is realized, that is, within a certain period of time, the discharge device in the circuit can simultaneously generate positively charged ions and negatively charged ions.

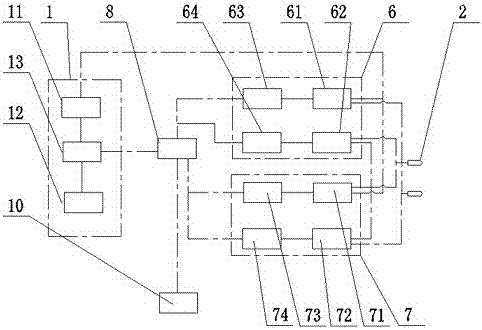

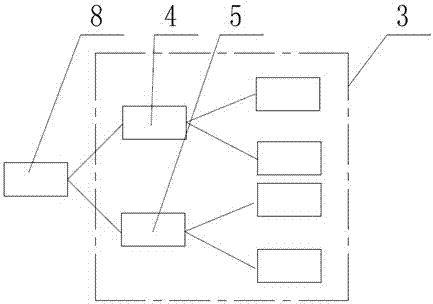

[0046] as attached figure 1 , attached figure 2 As shown, the interlocking high-voltage generating circuit includes a high-voltage power supply 1, an electrostatic discharge unit 2, a high-voltage generating circuit 3 and a main control unit 8;

[0047] The high-voltage power supply 1 includes a positive high-voltage power supply 11 and a negative high-voltage power supply 12. A power adjustment unit 13 is connected between t...

Embodiment 2

[0061] The overall structure of this embodiment is similar to that of Embodiment 1, and the difference is that: the number of the electrostatic discharge units 2 arranged below each of the FFU air outlets 9 is four, and the four electrostatic discharge units 2 are square or Rectangular distribution, they are provided with gaps and the gap distance is adjustable, one of the electrostatic discharge units 2 is connected to each high-voltage loop drive circuit, and two parallel electrostatic discharge units 2 are connected to the first high-voltage generating circuit 3, and the other Two are connected to the second high voltage generating circuit 4;

[0062] At this time, its working process is roughly similar to that of Embodiment 1, the difference being that: when the first high voltage generating circuit 3 is turned on and the second high voltage generating circuit 4 is disconnected, the first high voltage generating circuit 3 connected to the The two electrostatic discharge el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com