Device and method for testing rheologic property of coal mine filling slurry

A technology for filling slurry and rheological properties, which is applied in measurement devices, flow characteristics, analytical materials, etc., can solve the problems of few instruments, small size, and insufficient test accuracy, and achieve accurate measurement, simple and portable devices, and test methods. various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

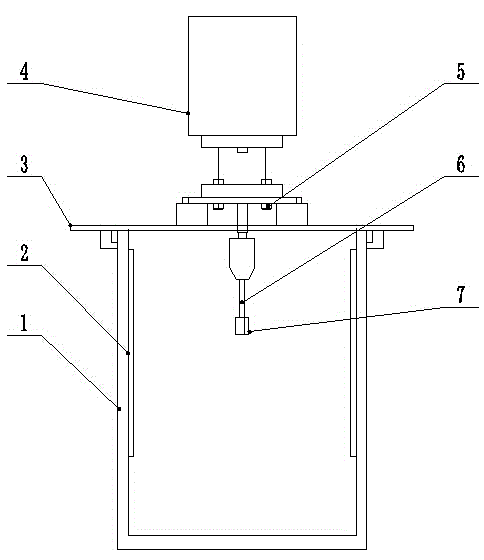

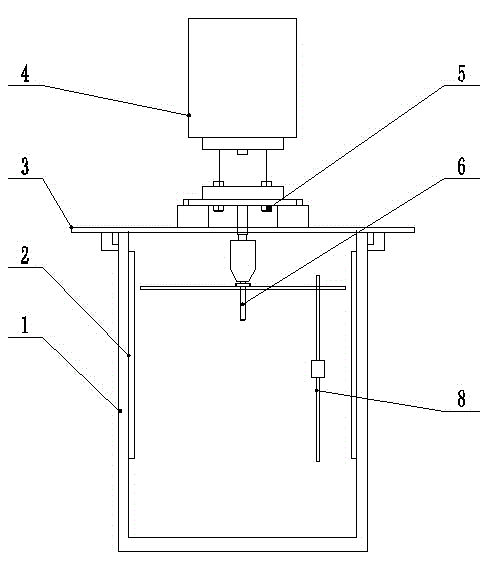

[0032] This embodiment provides the testing device and method of the present invention to measure the rheological properties of coal mine filling slurry.

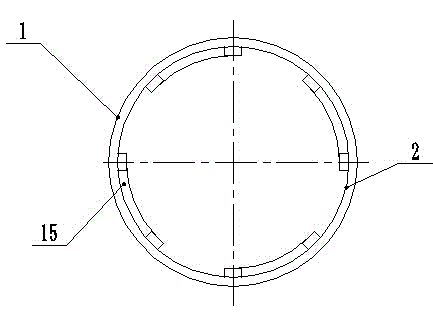

[0033] A rheological performance testing device for coal mine filling slurry, comprising an outer cylinder 1, an inner cylinder 2, a fixing plate 3, a torque sensor 4, a fastening nut 5, and a connecting rod 6; the inner cylinder 2 is provided inside the outer cylinder 1 , the inner wall of the outer cylinder 1 is in contact with the outer wall of the inner cylinder 2, the upper edge of the outer cylinder 1 is provided with a groove, and the fixing plate 3 is clamped with the card groove provided outside the outer cylinder 1 through the groove; the fixing plate 3 There is a circular groove on the top to engage with the inner cylinder 2, and the opening of the inner cylinder 2 is in the arc-shaped groove of the fixed plate 3, which effectively prevents the material from flowing out during the test; the upper part of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com