Sandstone wettability evaluating method

An evaluation method and wettability technology, which is used in the preparation of test samples, soil material testing, material inspection products, etc., and can solve the problem of complex testing process, inability to accurately reflect the wetting status, and sensitive to neutral wet samples. problems such as poor performance, to achieve the effect of reducing the siphon phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

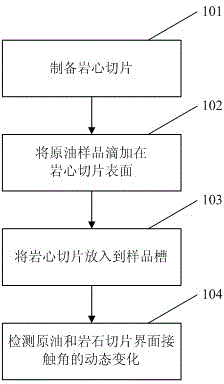

[0015] figure 1 It is a flow chart of a specific embodiment of the sandstone-based wettability evaluation method of the present invention. In step 101, a core slice is prepared. After the rock core sample to be tested is sliced, it is ground into a rock core slice with a thickness of less than 0.2 cm by polishing machine. The process goes to step 102.

[0016] In step 102, the crude oil sample to be tested is dropped on the surface of the core slice. At room temperature, drop 1.5 μL of the crude oil sample to be tested on the surface of the core slice prepared according to step 101. The process goes to step 103.

[0017] In step 103, the core slice is immersed in the solution in the sample chamber of the dynamic contact angle measuring instr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com