Engine noise testing method based on outfield airplane

A noise testing and engine technology, applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., to achieve accurate measurement and suppress noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention are described in detail below, and examples of the embodiments are shown in the accompanying drawings. This embodiment is to test a certain in-line six-cylinder engine. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention, but should not be construed as limiting the invention.

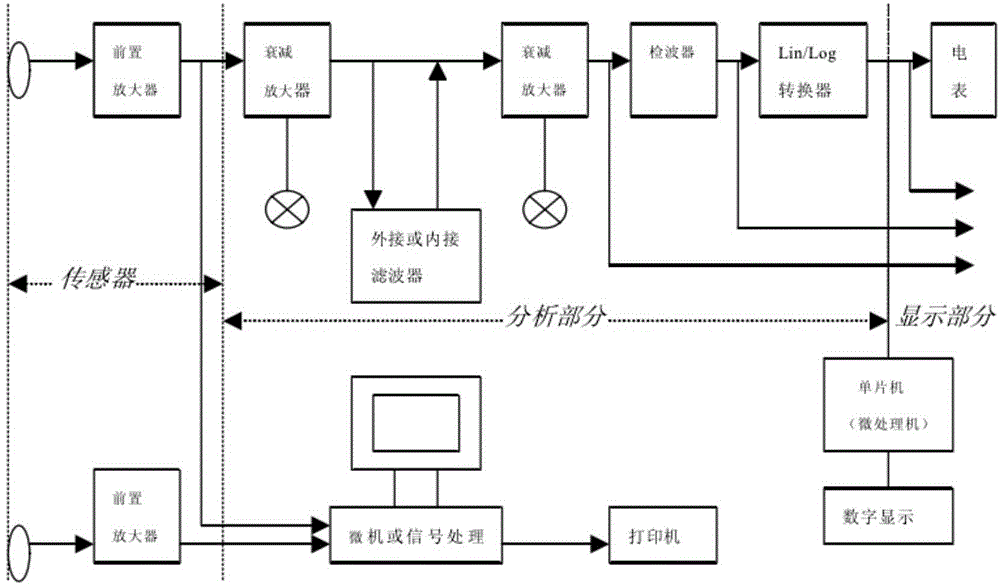

[0036] Reference figure 1 As shown, the test system of the present invention based on the engine noise test method of the outfield aircraft adopts the BSWA-VS302N (USB) dual-channel college entrance analyzer, which is composed of a sensor, an analysis part and a display part. The sensor adopts a sound pressure sensor, which is a An acoustic-electric converter is used to pick up signals and convert the measured acoustic signals into electrical signals; the analysis part includes a charge amplifier, A / D conversion board (digital signal processing), used to amplify, attenua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com