Novel light-arm-amplification type high-precision length sensor and measurement method thereof

A technology of length sensor and measurement method, which is applied in measurement devices, instruments, and optical devices, etc., can solve the problem of difficulty in improving measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

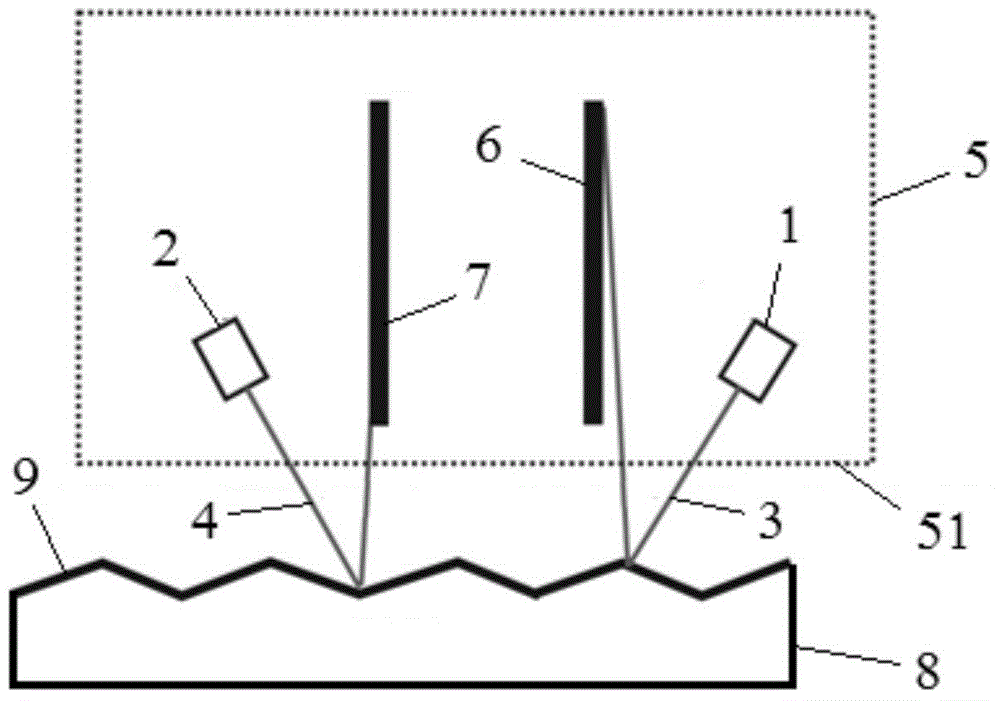

[0065] Such as Figure 1-7 As shown, a new optical arm amplified high-precision length sensor, including:

[0066] Laser beam one 3, laser beam two 4;

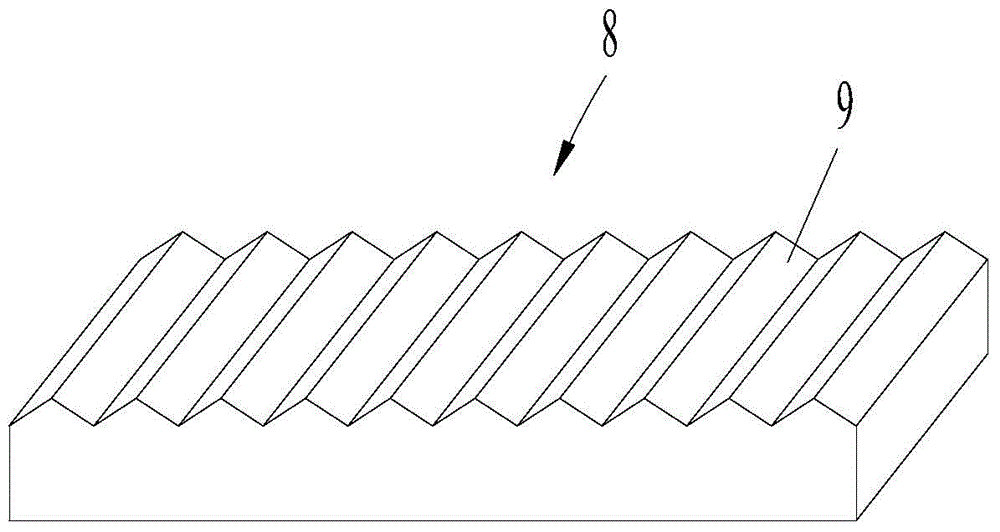

[0067] The reflective part 8 is provided with several reflective surfaces 9 for reflecting the laser beam one 3 and the laser beam two 4 on the reflective part 8, each reflective surface 9 has a symmetrical convex shape in section, and all the reflective surfaces 9 are connected end to end to form reflector array;

[0068] A photodetector 6 is used to receive the laser beam reflected by the reflective surface 9 of the reflective component 8 and display the reflected position of the laser beam 3;

[0069] The photodetector 2 7 is used to receive the laser beam reflected by the laser beam 2 4 on the reflective surface 9 in the reflective component 8 and display its reflection position;

[0070] The processing system calculates the displacement change of the measured object according to the change value of the reflection posit...

Embodiment 2

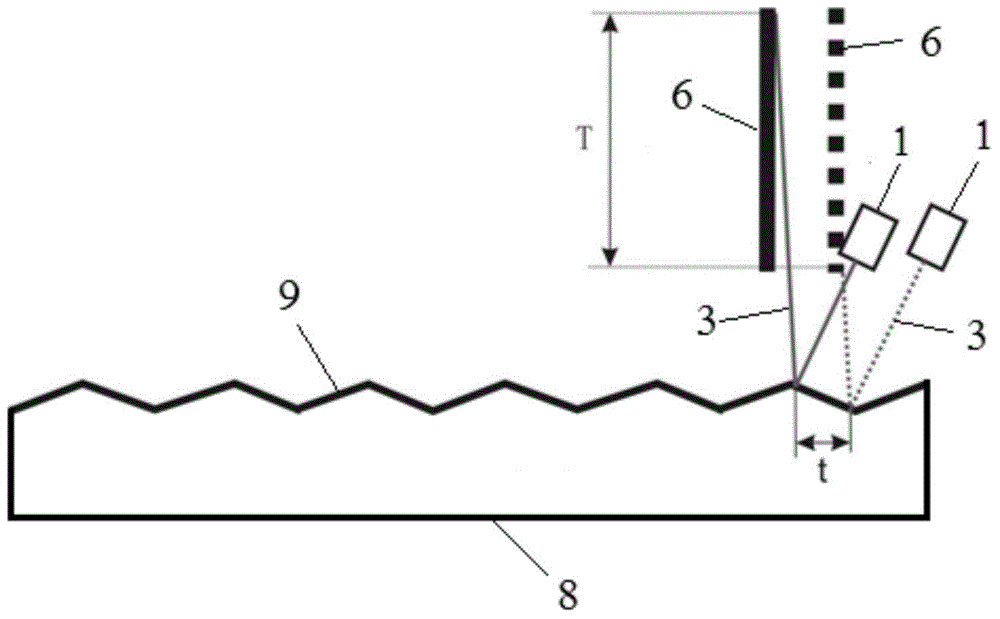

[0077] Such as Figure 6 As shown, a novel optical arm amplified high-precision length sensor measurement method includes the novel optical arm amplified high-precision length sensor as in Embodiment 1, and its measurement method includes the following steps:

[0078] Step 1. Fix the measured object on the reflective part 8 or the reading head 5, wherein the reflective surface 9 is adjusted to be consistent with the moving direction of the measured object, wherein the reflective part 8 is provided with an installation for easy fixing on the measured object hole or paste;

[0079] Step 2, adjust the positional relationship of laser beam 1 3, laser beam 2 4, reflector 8, photodetector 1 6, photodetector 2 7, make them mutually adaptable, make laser beam 1 3, laser beam 2 4 in The two laser beams reflected on the reflection member 8 can be detected by the photodetector one 6 and the photodetector two 7 respectively; and adjust the photodetector one 6, photodetector two 7 and the...

Embodiment 3

[0098] When the displacement value of the object to be measured is less than the reflection length of one of the reflection unit surfaces of a reflection surface 9 on the reflection component 8, the processing system does not need to switch and superimpose the two laser beams and photodetectors, and only needs to adopt the embodiment The laser beam 1 3 and the photodetector 1 6 in 2, or the laser beam 2 4 and the photodetector 2 7, cooperate with the reflection component 8 to measure the displacement of the measured object.

[0099] This embodiment is suitable for measuring one-time displacement of the measured object, or continuous incremental displacement values, and the continuous incremental displacement values are all smaller than the reflection length of one of the reflection unit surfaces of each reflection surface 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com