Energy-saving control method, system and device of combined gas condensing heat supply system

An energy-saving control system and heating system technology, applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of large footprint, inability to achieve reasonable load distribution and transfer, load fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

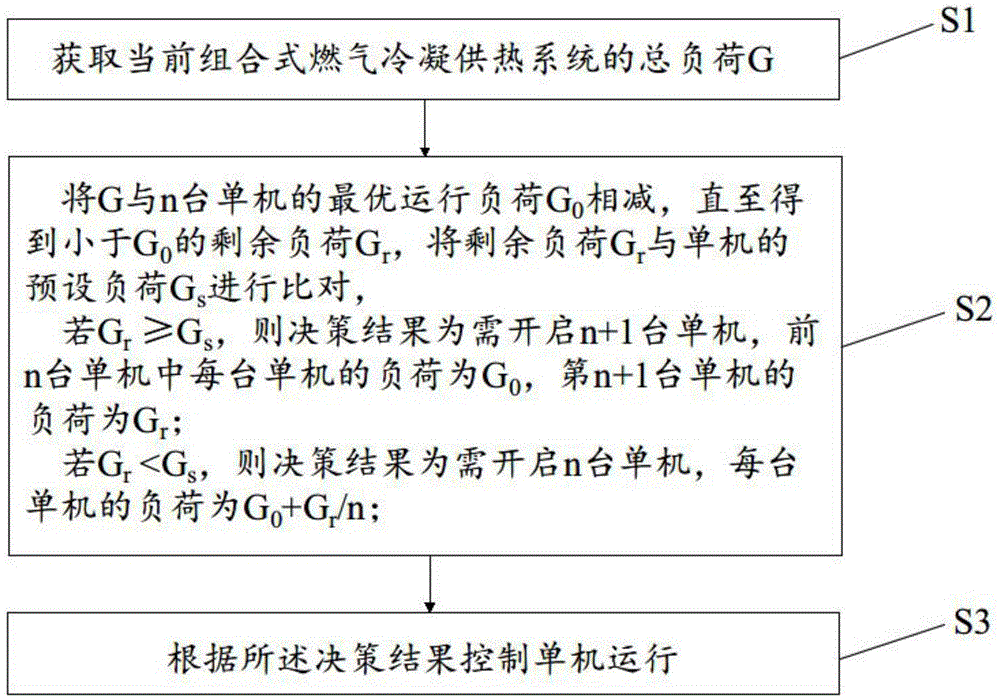

[0078] like figure 1 As shown, the present invention provides an energy-saving control method for a combined gas-fired condensing heating system. multiple gas-fired condensing heating units, the optimal operating load of each unit is G 0 , the method includes the following steps:

[0079] Assuming that when a single machine is running at full load, its load is G imax = 350KW, stand-alone operating efficiency η = 91.4%, then according to the formula η = G i / G imax , then G i =G 0 , calculate the optimal operating load G of a single machine 0 is 320KW.

[0080] S1. Obtain the total load G of the current combined gas condensing heating system;

[0081] Assume that the total load G of the current system is 1000KW.

[0082] S2. Compare G with the optimal operating load G of n single machines 0 subtract until you get less than G 0 The residual load G r , the residual load G r Preset load G with stand-alone s to compare,

[0083] If G r ≥G s , the decision result is...

Embodiment 2

[0150] like figure 1 As shown, the present invention provides an energy-saving control method for a combined gas-fired condensing heating system. multiple gas-fired condensing heating units, the optimal operating load of each unit is G 0 , the method includes the following steps:

[0151] Assuming that when a single machine is running at full load, its load is G imax = 500KW, stand-alone operating efficiency η = 95%, then according to the formula η = G i / G imax , then G i =G 0 , calculate the optimal operating load G of a single machine 0 is 475KW.

[0152] S1. Obtain the total load G of the current combined gas condensing heating system;

[0153] Assume that the total load G of the current system is 2500KW.

[0154] S2. Compare G with the optimal operating load G of n single machines 0 Subtract until you get less than G 0 The residual load G r , the residual load G r Preset load G with stand-alone s to compare,

[0155] If G r ≥G s , the decision result is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com