Steel wire rope connecting snap

A technology of steel wire rope and buckle, which is applied in the direction of transmission elements or pulley ropes or cables, textile cables, protective equipment, etc., and can solve problems such as inability to play a protective role, complex structure, and unfavorable processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

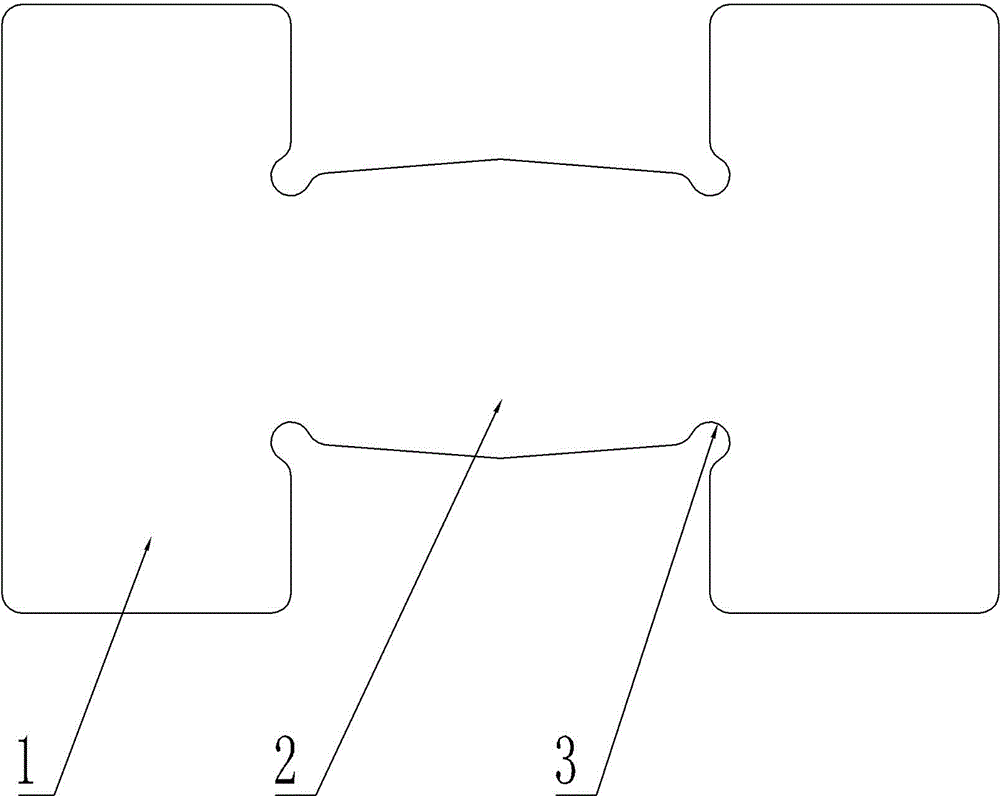

[0020] Embodiment 1: as figure 1 As shown, it includes connecting plate 2 and wing plate 1 combined in an "H" shape. The connecting plate 2 and wing plate 1 are integrally formed and the materials are all iron blocks. The wing plate 1 is arranged at both ends of the connecting plate 2. The wing plate 1 The width equals the circumference of steel wire rope, makes wing plate 1 just can wrap steel wire rope one circle. Such as figure 2 As shown, the connecting plate 2 is a circular arc plate that can fit on the surface of the steel wire rope. The arc of the connecting plate 2 is determined by the thickness of the steel wire rope, so that it can just wrap the steel wire rope in the circumferential direction, and the steel wire rope can be stuck in it when in use. . The inner surface of the connecting plate 2 is provided with convex teeth 4 to increase the friction between the connecting plate 2 and the steel wire and reduce the possibility of the steel wire rope sliding. The an...

Embodiment 2

[0022] Embodiment 2: In addition to being able to combine the connecting plate 2 and the wing plate 1 to form an "H" shape, it can also be deformed, such as Figure 4 As shown, in the shape of "n", the fastening function of the present invention can also be realized.

Embodiment 3

[0023] Embodiment 3: Except that connecting plate 2 and wing plate 1 can be combined into "H" shape and "n" shape, it can also be deformed, such as Figure 5 As shown, it is in the shape of "Z", which can also realize the fastening function of the present invention.

[0024] The present invention is simple in structure, easy to manufacture, and convenient to use. Two steel wire ropes with the same shape and size are used in conjunction with buckles, and the cross joints of the steel wire ropes are wrapped and pressed through the wing plate 1 and the connecting plate 2, and the force is large. It effectively prevents the sliding of the joints and achieves the purpose of fastening the steel wire mesh; after the fastening, the cross joints are tightly wrapped and closed by the buckle, which reduces the infiltration of external rainwater and can better prevent the inner layer of the buckle and the connection between the wire rope The steel wire is oxidized and corroded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com