Method for synthesizing polyaniline nanotubes

A technology of nanotubes and polyaniline, which is applied in the preparation and application of nanomaterials, and can solve the problems that there are no polyaniline nanotubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Add the aniline monomer to the aqueous solution of camphorsulfonic acid with a concentration of 3.5 g / L, stir for 10 minutes until it is uniformly dispersed, and place it under a steady-state static magnetic field (magnetic field strength of 5 Tesla) at 25 degrees Celsius. Put 1 hour; The mol ratio of camphorsulfonic acid and aniline monomer is 1:1;

[0021] (2) Take 10 g / L ammonium persulfate aqueous solution and add it dropwise to the dispersion liquid obtained in the above steps. The reaction temperature is controlled at 25 degrees Celsius. 5 Tesla), continue to stand still for 24 hours; the molar ratio of ammonium persulfate to aniline monomer is 1:1;

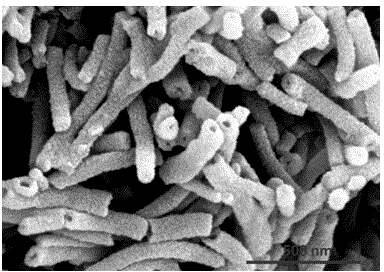

[0022] (3) Suction filter the product obtained above, wash with distilled water and absolute ethanol respectively until the filtrate is colorless, place in a vacuum oven at 60°C, and dry in vacuum for 20 hours to obtain polyaniline nanotubes. figure 1 Scanning electron micrograph of the prepared polyaniline nan...

Embodiment 2

[0024] (1) Add the aniline monomer to the aqueous solution of 2 g / L camphorsulfonic acid, stir for 10 minutes until it is uniformly dispersed, and place it under a steady-state static magnetic field (magnetic field strength of 1 Tesla) at 20 degrees Celsius. Put 1 hour; The mol ratio of camphorsulfonic acid and aniline monomer is 4:1;

[0025] (2) Take 5 g / L of ammonium persulfate aqueous solution and add it dropwise to the dispersion liquid obtained in the above steps. The reaction temperature is controlled at 20 degrees Celsius. After the dropwise addition, place the reaction mixture solution in a steady state static magnetic field ( The magnetic field strength is 1 Tesla), and continue to stand still for 24 hours; the molar ratio of ammonium persulfate to aniline monomer is 2:1;

[0026] (3) Suction filter the product obtained above, wash with distilled water and absolute ethanol respectively until the filtrate is colorless, place in a vacuum oven at 60°C, and dry in vacuum...

Embodiment 3

[0028] (1) Add the aniline monomer to the aqueous solution of 2.5 g / L camphorsulfonic acid, stir for 10 minutes until it is uniformly dispersed, and place it under a steady-state static magnetic field (magnetic field strength of 10 Tesla) at 30 degrees Celsius. Put 1 hour; The mol ratio of camphorsulfonic acid and aniline monomer is 2:1;

[0029] (2) Take 20 g / L of ammonium persulfate aqueous solution and add it dropwise to the dispersion liquid obtained in the above steps. The reaction temperature is controlled at 30 degrees Celsius. After the dropwise addition, place the reaction mixture solution in a steady state static magnetic field ( The magnetic field strength is 10 tesla), and the reaction is continued for 24 hours; the molar ratio of ammonium persulfate to aniline monomer is 1:2;

[0030] (3) Suction filter the product obtained above, wash with distilled water and absolute ethanol respectively until the filtrate is colorless, place in a vacuum oven at 60°C, and dry in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com