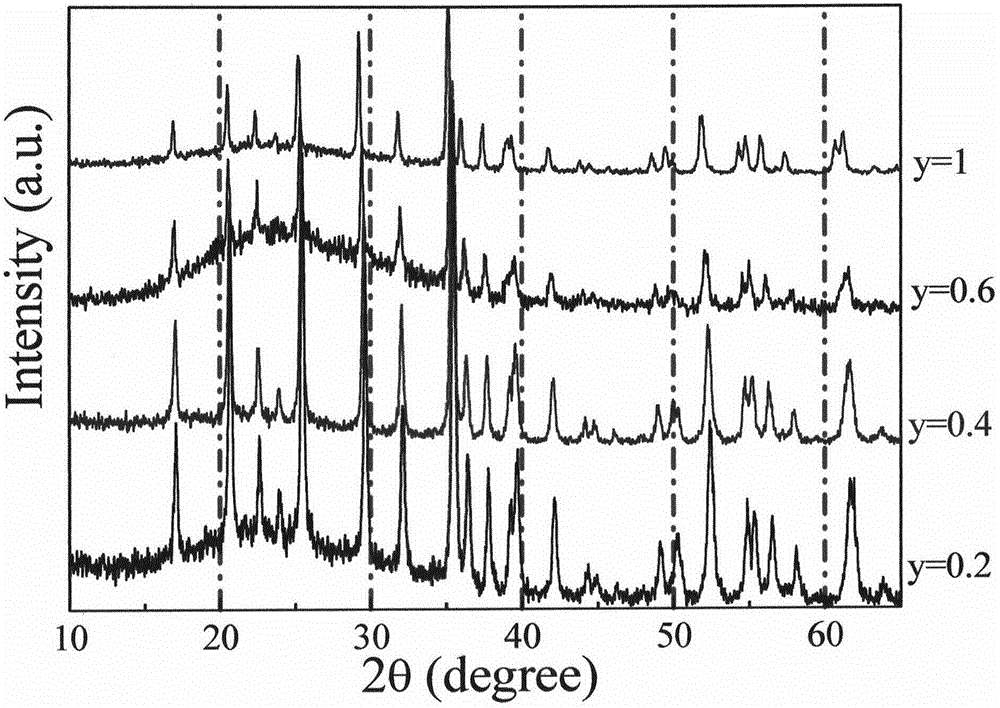

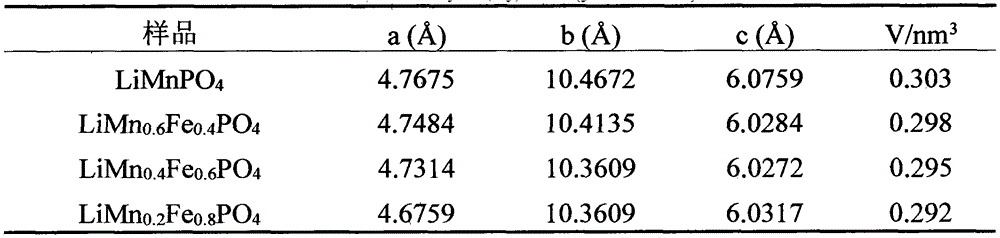

LiMnyFe(1-y)PO4 micron material, preparation method thereof and application thereof

A technology of PO4 and synthesis method, which is applied in the field of doped materials, can solve problems such as instability and difficulty in obtaining material capacity, and achieve an effect that is conducive to insertion and extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

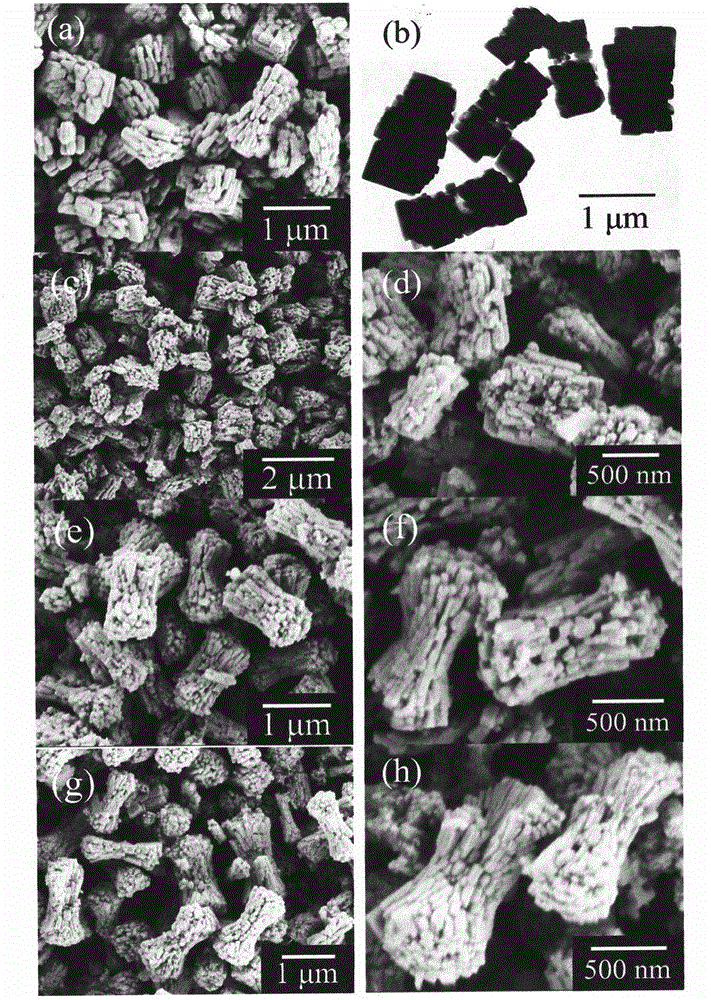

Embodiment 1

[0021] This embodiment provides a LiMn y Fe (1-y) PO 4 (y=0.2) the solvothermal synthesis method of micron material, comprises the following steps:

[0022] (1) Dissolve 2.5mmol LiI and 1.25mmol PVP in 30mL of benzyl alcohol solvent, stir to fully dissolve into transparent solution I;

[0023] (2) Then 0.05mmol MnCl 2 4H 2 O and 0.2 mmol FeCl 3 ·6H 2 O was dissolved in 30 mL of benzyl alcohol to form a colorless and transparent solution II;

[0024](3) Mix and stir the transparent solution I obtained in step (1) and the colorless transparent solution II obtained in step (2); then add 0.02mL of 85% H in the mixed solution 3 PO 4 , fully stirred for 20 minutes and transferred to an 80mL reaction kettle, reacted at 150°C for 48 hours, took it out to cool naturally, centrifuged with absolute ethanol and distilled water for 3 to 5 times, and dried in the air for 6 hours to obtain LiMn 0.2 Fe 0.8 PO 4 micron material.

Embodiment 2

[0026] This embodiment provides a LiMn y Fe (1-y) PO 4 (y=0.4) the solvothermal synthesis method of micron material, comprises the following steps:

[0027] (1) Dissolve 2.5mmol LiI and 1.25mmol PVP in 30mL of benzyl alcohol solvent, stir to fully dissolve into transparent solution I;

[0028] (2) Then add 0.1mmol MnCl 2 4H 2 O and 0.15 mmol FeCl 3 ·6H 2 O was dissolved in 30 mL of benzyl alcohol to form a colorless and transparent solution II;

[0029] (3) Mix and stir the transparent solution I obtained in step (1) and the colorless transparent solution II obtained in step (2); then add 0.02mL of 85% H in the mixed solution 3 PO 4 , fully stirred for 20 minutes and transferred to an 80mL reaction kettle, reacted at 150°C for 48 hours, took it out to cool naturally, centrifuged with absolute ethanol and distilled water for 3 to 5 times, and dried in the air for 6 hours to obtain LiMn 0.4 Fe 0.6 PO 4 micron material.

Embodiment 3

[0031] This embodiment provides a LiMn y Fe (1-y) PO 4 (y=0.6) the solvothermal synthesis method of micron material, comprises the following steps:

[0032] (1) Dissolve 2.5mmol LiI and 1.25mmol PVP in 30mL of benzyl alcohol solvent, stir to fully dissolve into transparent solution I;

[0033] (2) Then 0.15mmol MnCl 2 4H 2 O and 0.1 mmol FeCl 3 ·6H 2 O was dissolved in 30 mL of benzyl alcohol to form a colorless and transparent solution II;

[0034] (3) Mix and stir the transparent solution I obtained in step (1) and the colorless transparent solution II obtained in step (2); then add 0.02mL of 85% H in the mixed solution 3 PO 4 , fully stirred for 20 minutes and transferred to an 80mL reaction kettle, reacted at 150°C for 48 hours, took it out to cool naturally, centrifuged with absolute ethanol and distilled water for 3 to 5 times, and dried in the air for 6 hours to obtain LiMn 0.6 Fe 0.4 PO 4 micron material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com