A wind turbine blade turning device

A technology of wind power blade and turning device, which is applied in the direction of turning objects, transportation and packaging, pile separation, etc., can solve the problems of low turning efficiency, laborious operation, and inability to ensure blade torque, and achieves increasing rotational torque and reducing driving force. , weight reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically illustrate the wind turbine blade turning device provided by the present invention in conjunction with the accompanying drawings.

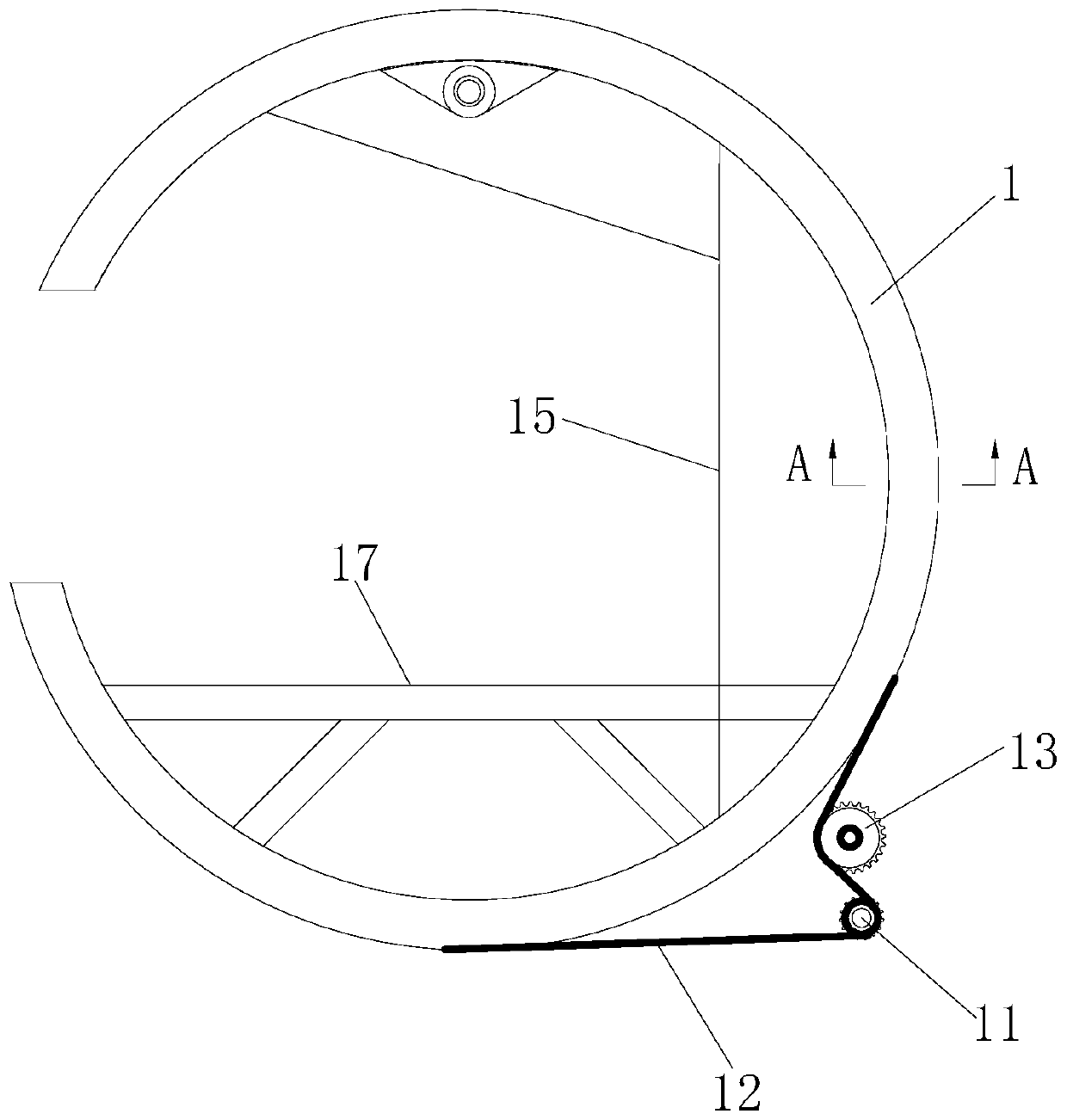

[0023] Such as figure 1 As shown, the wind turbine blade turning device provided in this embodiment includes: a swivel 1, a clamping mechanism, a supporting base 2, and a driving mechanism.

[0024] Specifically, the clamping mechanism is installed in the swivel 1 and turns over synchronously with the swivel 1 . In this embodiment, the clamping mechanism includes a fixed clamp arm 3 , a movable clamp arm 4 matching the fixed clamp arm 3 , and a link assembly for driving the movable clamp arm 4 to deflect. Wherein, the fixed clamping arm 3 has a first clamping surface 31, the movable clamping arm 4 is an L-shaped structure and has a second clamping surface 41 facing the first cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com