A solid-liquid separation centrifuge

A solid-liquid separation and centrifuge technology, applied in the field of centrifuges, can solve the problems of liquid flow disturbance, reduce solid discharge, affect separation effect, etc., and achieve improved centrifugal separation efficiency, improved centrifugal separation efficiency, and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

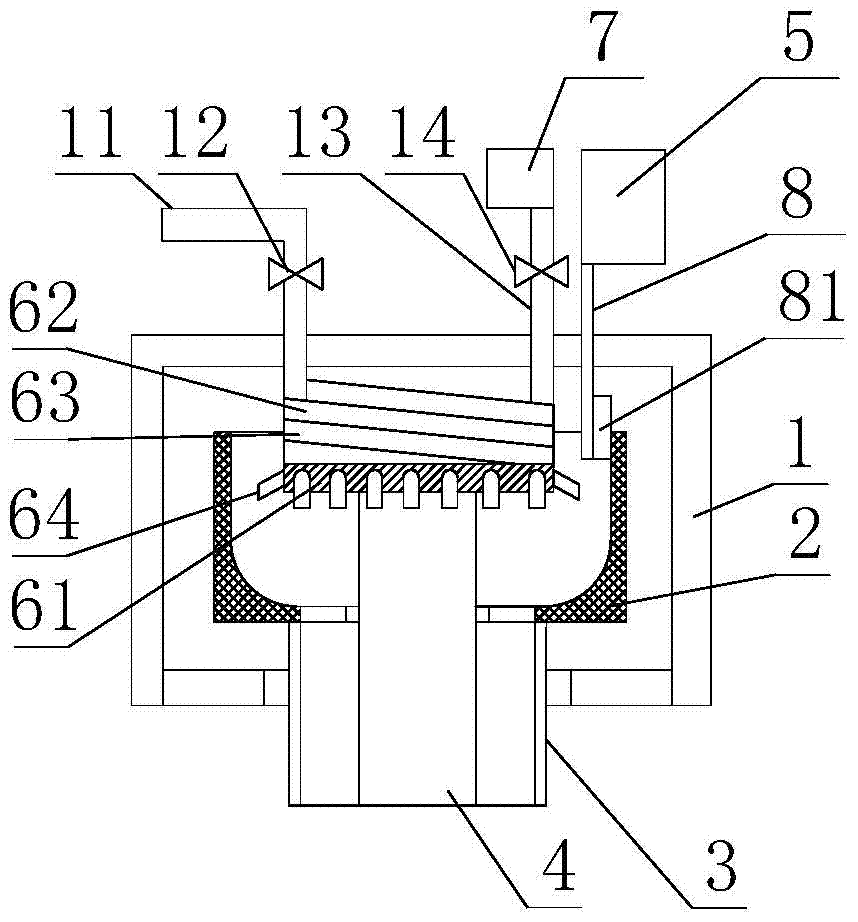

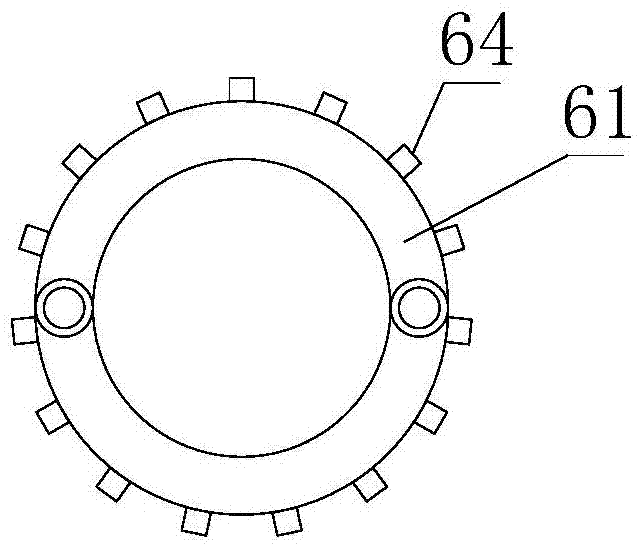

[0015] Such as figure 1 and 2 as shown, figure 1 It is a structural schematic diagram of a solid-liquid separation centrifuge proposed by the present invention, figure 2 for figure 1 A schematic top view of the annular jet in .

[0016] refer to figure 1 and 2 , a solid-liquid separation centrifuge proposed by the present invention, comprising: a casing 1, a drum 2, a discharge cylinder 3, a first driving device 4, a second driving device 5, a flow guide mechanism, an air injection mechanism 7, a scraper rod 8;

[0017] There is a cavity inside the casing 1, the bottom of the cavity has a first outlet for discharging solids and a second outlet for discharging liquid, the top of the casing 1 is provided with a liquid inlet and an air inlet, and the liquid inlet is provided with The liquid inlet pipe 11 is provided with a first valve 12, the air inlet is provided with an air inlet pipe 13, and the air inlet pipe 13 is provided with a second valve 14, and the end of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com