Energy-saving type pasteurizer

A pasteurization machine, energy-saving technology, applied in food science, food preservation, application, etc., can solve the problems of high labor intensity, unstable sterilization quality, and large temperature difference between the upper and lower layers of the sterilization pool, and achieve simple and convenient cleaning of impurities. The effect of convenient control and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

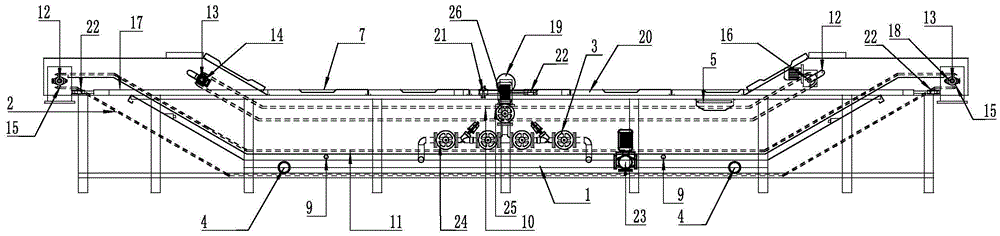

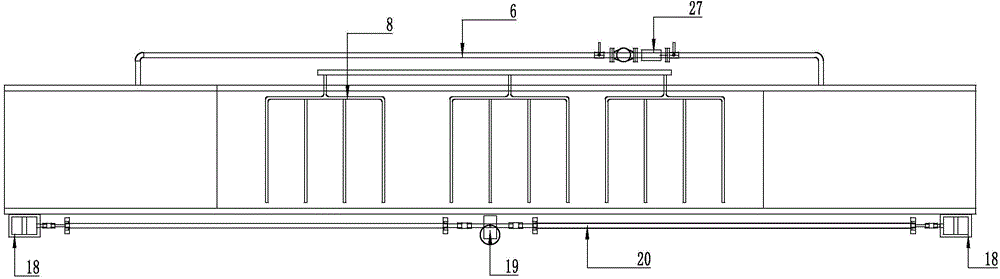

[0014] Such as figure 1 , 2 As shown, the energy-saving pasteurizer includes a tank body 1, a conveying system 2, and a steam heating system 3. A drain butterfly valve 4 is welded on both sides of the bottom of the tank body 1, and one of the drain butterfly valves 4 is provided on the tank body 1 Overflow port 5; steam heating system 3 is composed of steam heating pipe 8, circulating water pump 23, stop valve 24, steam solenoid valve 25, self-operated temperature control valve 26, circulating water pipe 6, filter 27, and temperature control system 9, circulating The water pipe 6 is located on one side of the tank body 1, and the two ends of the circulating water pipe 6 are respectively connected with the two ends of the tank body 1, and a filter 27 is arranged on the circulating water pipe 6. The circulating water pipe 6 is driven to circulate water through the circulating water pump 23. There are three sets of steam heating pipes 8 in the body 1. The three sets of steam he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com