Compound polarizing lens and manufacturing method thereof

A technology of polarizing lenses and manufacturing methods, which is applied in optics, optical parts, optical components, etc., can solve problems such as lens springback deformation, high difficulty in lens production, and lens exceeding the standard, and achieve the effect of reasonable polarizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A composite polarizing lens of the present invention comprises a PVA polarizing film, a TAC base material and a resin lens. The film is set between the TAC substrate and the resin mirror substrate. The thickness of the PVA film is 0.03mm, the thickness of the TAC substrate is 0.4mm, and the thickness of the thinnest part of the resin lens is 1.5mm. The TAC substrate and the PVA polarizing film Between them is casting bonding, the lamination and connection between the TAC base material and the PVA polarizing film and the resin lens is the bonding of UV glue and photocatalyst irradiated by UV light.

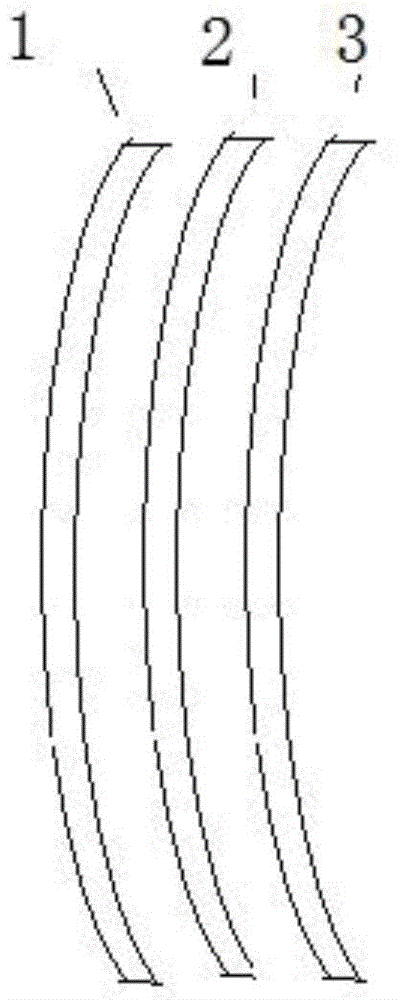

[0019] refer to figure 1 It can be seen that the PVA polarizing film and the TAC base material are arranged on the outer surface of the resin lens.

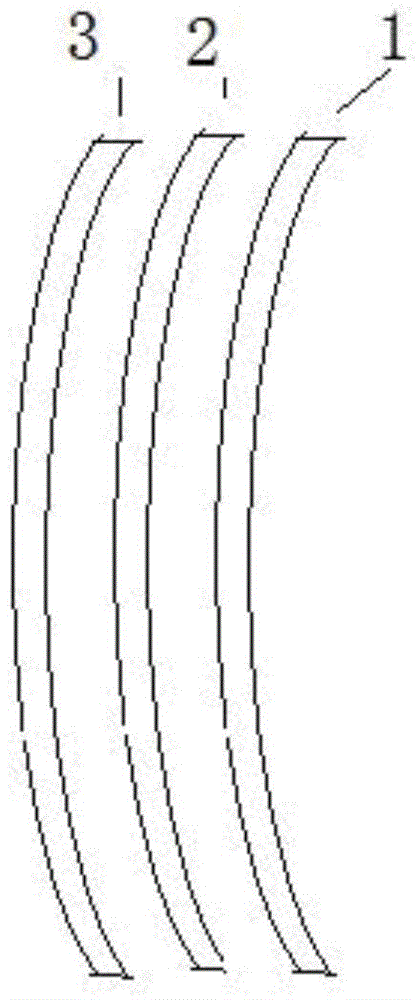

[0020] refer to figure 2 It can be seen that the PVA polarizing film and the TAC base material are arranged on the inner surface of the resin lens.

[0021] A kind of manufacture method of composite polarized lens of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com