A new type of dry process cement kiln preheating predecomposition system and method

A pre-decomposition and cement kiln technology, applied in the field of preheating and pre-decomposition system of dry process cement kiln, can solve the problems of investment and operation difficulty, increase of failure points, difficulty of existing system transformation, difficulty of promotion, etc., and achieve system output Improvement, output improvement, and the effect of increasing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

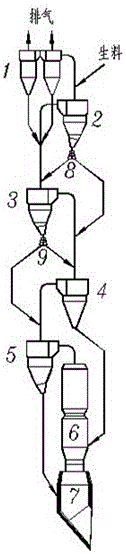

[0026] A dry-process cement kiln preheating and pre-decomposing system, including a first-stage preheater 1, a second-stage preheater 2, a third-stage preheater 3, a fourth-stage preheater 4, and a fifth-stage preheater 5, starting from the first stage preheater 1, the air inlet pipe of each stage preheater communicates with the air outlet of the next stage preheater, so it is connected in turn until the fifth stage preheater 5, the first stage The air inlet pipe of the five-stage preheater 5 communicates with the top of the calciner 6 , and the bottom of the calciner 6 communicates with the kiln tail smoke chamber 7 .

[0027] A fine distributing device-8 is installed at the discharge port at the bottom of the second-stage preheater 2, and the discharge pipe of the fine distributing device-8 is divided into two paths, one of which communicates with the air inlet pipe of the second-stage preheater 2 , and the other way communicates with the air inlet pipe of the third-stage pr...

Embodiment 2

[0029] A dry-process cement kiln preheating and pre-decomposing system, including a first-stage preheater 1, a second-stage preheater 2, a third-stage preheater 3, a fourth-stage preheater 4, and a fifth-stage preheater 5, starting from the first stage preheater 1, the air inlet pipe of each stage preheater communicates with the air outlet of the next stage preheater, so it is connected in turn until the fifth stage preheater 5, the first stage The air inlet pipe of the five-stage preheater 5 communicates with the top of the calciner 6 , and the bottom of the calciner 6 communicates with the kiln tail smoke chamber 7 .

[0030] A fine distribution device 29 is installed at the discharge port at the bottom of the third stage preheater 3, and the discharge pipe of the fine distribution device 29 is divided into two paths, one of which communicates with the air inlet pipe of the third stage preheater 3 , and the other way communicates with the air inlet pipe of the fourth-stage p...

Embodiment 3

[0032] Such as figure 1 As shown, a dry process cement kiln preheating pre-decomposition system includes a first-stage preheater 1, a second-stage preheater 2, a third-stage preheater 3, a fourth-stage preheater 4, and a fifth-stage preheater. Stage preheater 5, starting from the first stage preheater 1, the air inlet pipe of each stage preheater communicates with the air outlet of the next stage preheater, so connected in turn until the fifth stage preheater 5, The air inlet pipe of the fifth-stage preheater 5 communicates with the top of the calciner 6 , and the bottom of the calciner 6 communicates with the kiln tail smoke chamber 7 .

[0033] A fine distributing device-8 is installed at the discharge port at the bottom of the second-stage preheater 2, and the discharge pipe of the fine distributing device-8 is divided into two paths, one of which communicates with the air inlet pipe of the second-stage preheater 2 , and the other way communicates with the air inlet pipe o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com