Combined technology of cluster perforation and stage fracturing

A staged fracturing and clustering technology, which is applied in the field of oil and gas field exploration and development, can solve the problems of difficulty in forming network fractures in oil and gas reservoirs, low timeliness for oil testing of oil and gas wells, and stuck guns, so as to avoid the risk of polluting oil and gas layers , Improve the effect of protecting oil and gas production layers and improving the efficiency of well completion operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A combined cluster perforation and stage fracturing process, comprising the following steps:

[0035] a. Determine the clustering of the perforation section according to the logging interpretation results, staged fracturing or volume fracturing process requirements;

[0036] b. Run in the completion string, run in the completion tools, set the packer according to the design requirements, and replace the completion fluid;

[0037] c. The first section of perforation operation is completed by adopting the cluster perforation technology conveyed by the pressure cable through the tubing;

[0038] d. Fracturing construction;

[0039] e. After the first stage of fracturing is completed, put in degradable fiber temporary plugging balls to block the perforation holes, and repeat the second stage of clustered perforation and fracturing until the perforation and fracturing operations of the entire well are completed.

[0040] In the step b, after the wellbore is cemented and co...

Embodiment 2

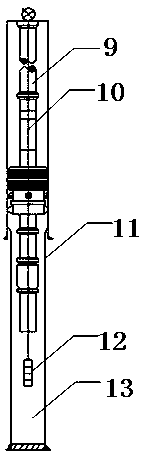

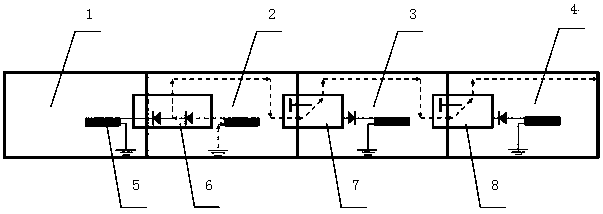

[0051] The present embodiment further illustrates the present invention in conjunction with the accompanying drawings:

[0052] like figure 1 After the wellbore 11 is cemented and completed, the completion string 9 is run in, the packer is set, and the completion fluid 13 is replaced to prepare for clustered perforation. After the cable blowout preventer is installed at the wellhead, the cable 10 is used to lower the clustered perforation pipe string 12, and after the first cluster is ignited, it is lifted up a certain distance to carry out the subsequent clusters of ignition operations in sequence. After the ignition is completed, the clustered perforation strings are pulled out to prepare for fracturing. Carry out the first stage of fracturing operation according to the fracturing procedure. After the fracturing is completed, put in the degradable fiber temporary plugging ball to block the perforation holes, and prepare for the second stage of perforation operation. In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com