Oil production wellhead gate valve under pressure replacement device and gate valve under pressure replacement method

A replacement method and gate valve technology, which are used in earth-moving drilling, wellbore/well components, etc., can solve the problems of time-consuming and labor-intensive, affecting the progress of oil production, increasing workload, etc., achieving simple device structure, improving maintenance and replacement efficiency, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

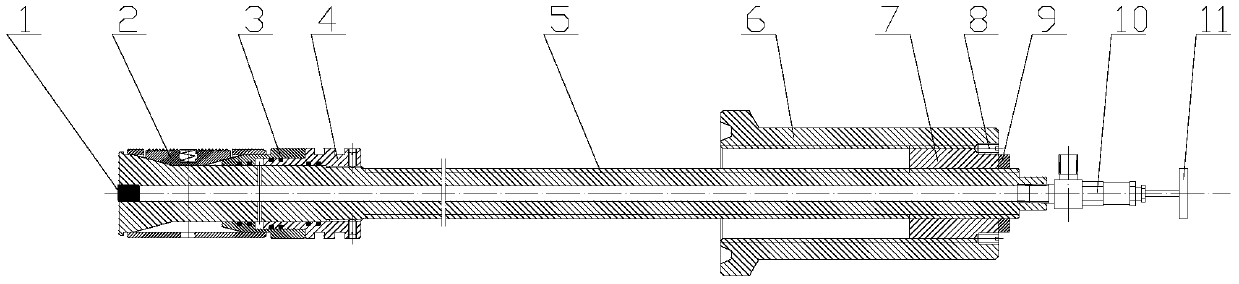

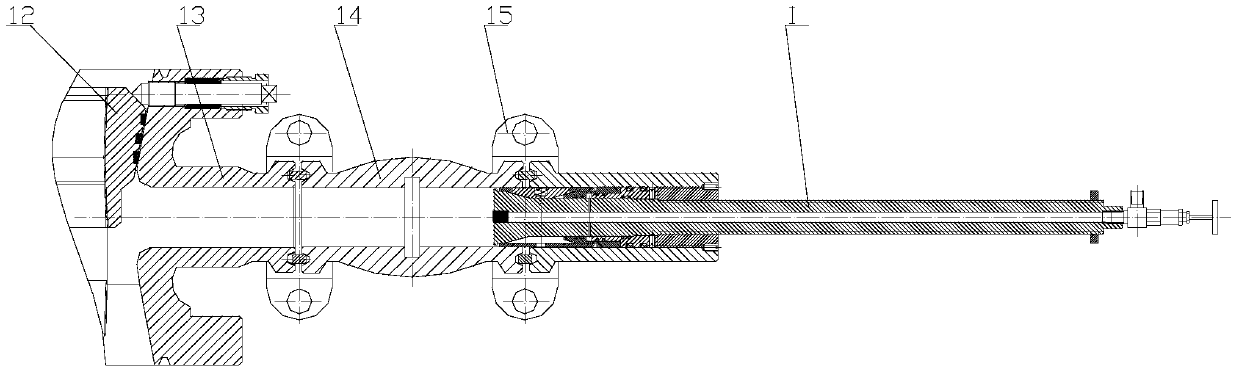

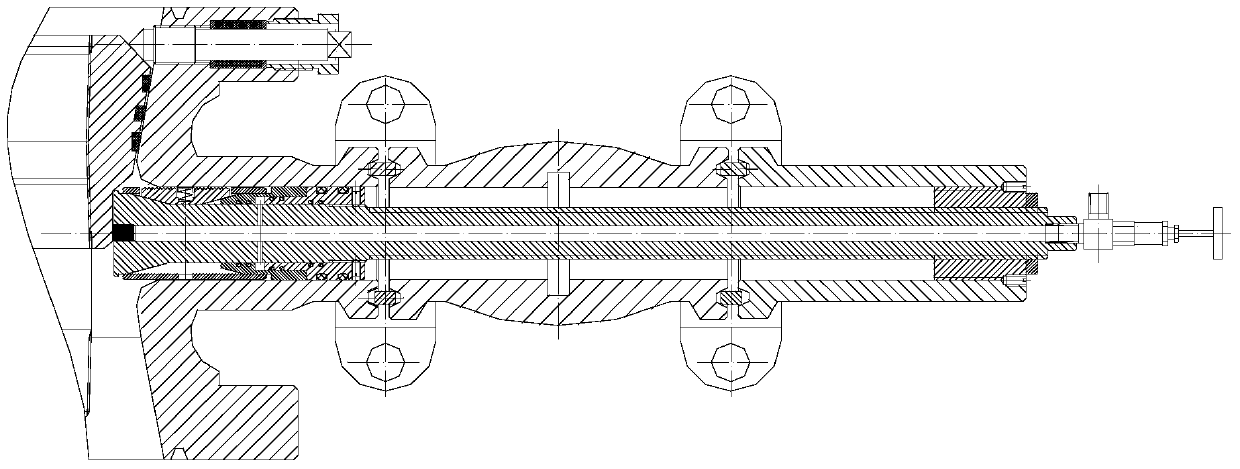

[0028] See figure 1 , is a structural schematic diagram of the device of the present invention, the oil production wellhead gate valve pressurized replacement device of the present invention includes a screw shaft 5, a slip assembly 2, a hydraulic cylinder 3, a sealing sleeve 4, an outer casing 6, and a screw nut 7 , shut-off valve 10 and hydraulic joint 11, wherein the slip assembly 2 and the hydraulic cylinder 3 are set on the optical axis section of the front part of the screw shaft 5, and the rear part of the hydraulic cylinder 3 is sealed by the sealing sleeve 4; The bar section is fitted with an outer casing 6 through a lead screw nut 7, and is fixed by a lock nut 9. The inner side of the outer casing 6 has a shape suitable for connecting with the clamp 15; the middle part of the screw shaft 5 is provided with a long hydraulic oil hole, thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com