Solvent-free synthetic leather production method using rotation teflon and specially-used production line

A production method and Teflon technology, applied in the field of synthetic leather manufacturing, can solve the problems of complex production line structure, increase process difficulty, increase production cost, etc., and achieve the advantages of saving production resources and energy consumption, reducing operating procedures, and avoiding environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

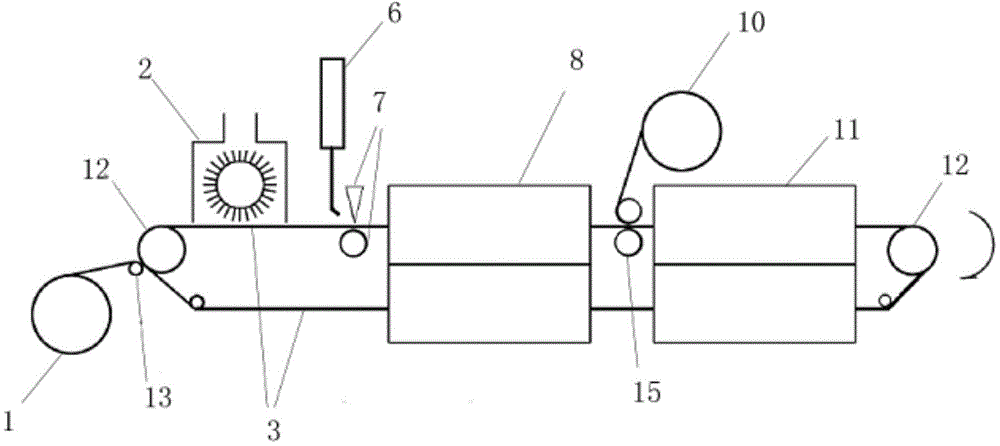

[0054] Such as figure 1 As shown, the present invention adopts the solvent-free synthetic leather special-purpose production line of rotary Teflon, comprises circulating type Teflon continuous conveyer belt 3, rotary device 12, and the cleaning and dust removal device 2 that distributes successively along conveyer belt 3 conveying direction and returning direction, with A coating device for coating the synthetic leather raw material on the conveyor belt 3 to obtain a processing layer, a compound processing device for pressing and compounding the base material to the processing layer to obtain a composite layer, an oven 11, a stripping device 13 and a winding device 1; Wherein, the conveyor belt 3 realizes the circular transmission of returning along the opposite direction of conveying and conveying along the conveying direction through the turning device 12 .

[0055] The coating device of the present invention is a feeding machine 6 and a coating mechanism arranged in sequenc...

Embodiment 2

[0063] Such as figure 2 As shown, the present invention adopts the solvent-free synthetic leather special-purpose production line of rotary Teflon, comprises circulating type Teflon continuous conveyer belt 3, rotary device 12, and the cleaning and dust removal device 2 that distributes successively along conveyer belt 3 conveying direction and returning direction, with A coating device for coating the synthetic leather raw material on the conveyor belt 3 to obtain a processing layer, a compound processing device for pressing and compounding the base material to the processing layer to obtain a composite layer, an oven 11, a stripping device 13 and a winding device 1; Wherein, the conveyor belt 3 realizes the circular transmission of returning along the opposite direction of conveying and conveying along the conveying direction through the turning device 12 .

[0064] The composite processing device of the present invention is an unwinding device 10 and a composite mechanism;...

Embodiment 3

[0072] Such as image 3 As shown, the present invention adopts the solvent-free synthetic leather special-purpose production line of rotary Teflon, comprises circulating type Teflon continuous conveyer belt 3, rotary device 12, and the cleaning and dust removal device 2 that distributes successively along conveyer belt 3 conveying direction and returning direction, with A coating device for coating the synthetic leather raw material on the conveyor belt 3 to obtain a processing layer, a compound processing device for pressing and compounding the base material to the processing layer to obtain a composite layer, an oven 11, a stripping device 13 and a winding device 1; Wherein, the conveyor belt 3 realizes the circular transmission of returning along the opposite direction of conveying and conveying along the conveying direction through the turning device 12 .

[0073] The coating device of the present invention is a feeder 6 and a coating mechanism arranged in sequence, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com