Mechanical clutch device for deceleration clutch of washing machine

A deceleration clutch and mechanical clutch technology, applied in the field of washing machines, can solve the problems of loud impact sound, high speed, and no energy saving, and achieve the effect of simple and reliable transmission structure and reducing impact sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

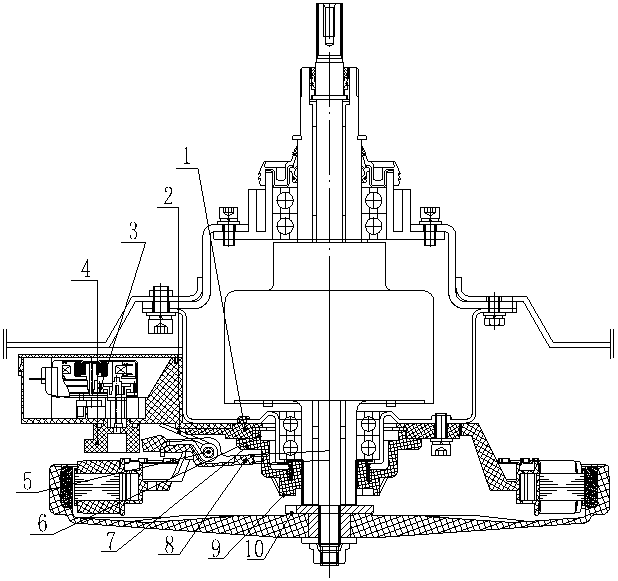

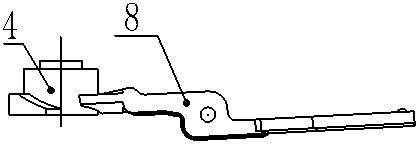

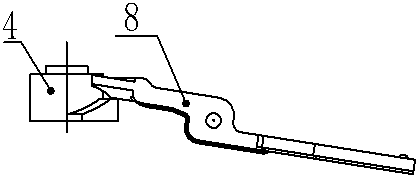

[0023] to combine Figure 1 to Figure 8 , which is a schematic structural diagram of an embodiment of the deceleration clutch of the washing machine of the present invention, which includes a slider 7, which is installed on the lower shaft sleeve of the deceleration clutch through a spline to slide up and down, and the slider 7 is coaxially installed with the lower shaft sleeve, It meshes with the spline teeth of the lower bushing and can slide up and down. The slider 7 is movably connected with one end of the lever 8 and is controlled by the lever 8 to slide up and down. The lever 8 slides and rotates coaxially through the reset torsion spring 2 of the lever. The other end of the driving rod 8 is movably connected with the crank 4, and the crank 4 is coaxially fixedly connected with the synchronous motor 3 and installed on the housing of the deceleration clutch; the upper end of the slider 7 There is an upper clutch tooth 6 on the slider, which is clutched with the washing cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com