Preparation process of novel grass rotted edible mushroom cultivation raw materials

A production process and grass decay technology, which is applied in the field of production process of new-type grass decay edible fungi cultivation raw materials, can solve the problems of low output and efficiency, large energy consumption, underutilized straw, etc., and save energy and labor. , the effect of reducing labor costs and reducing nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

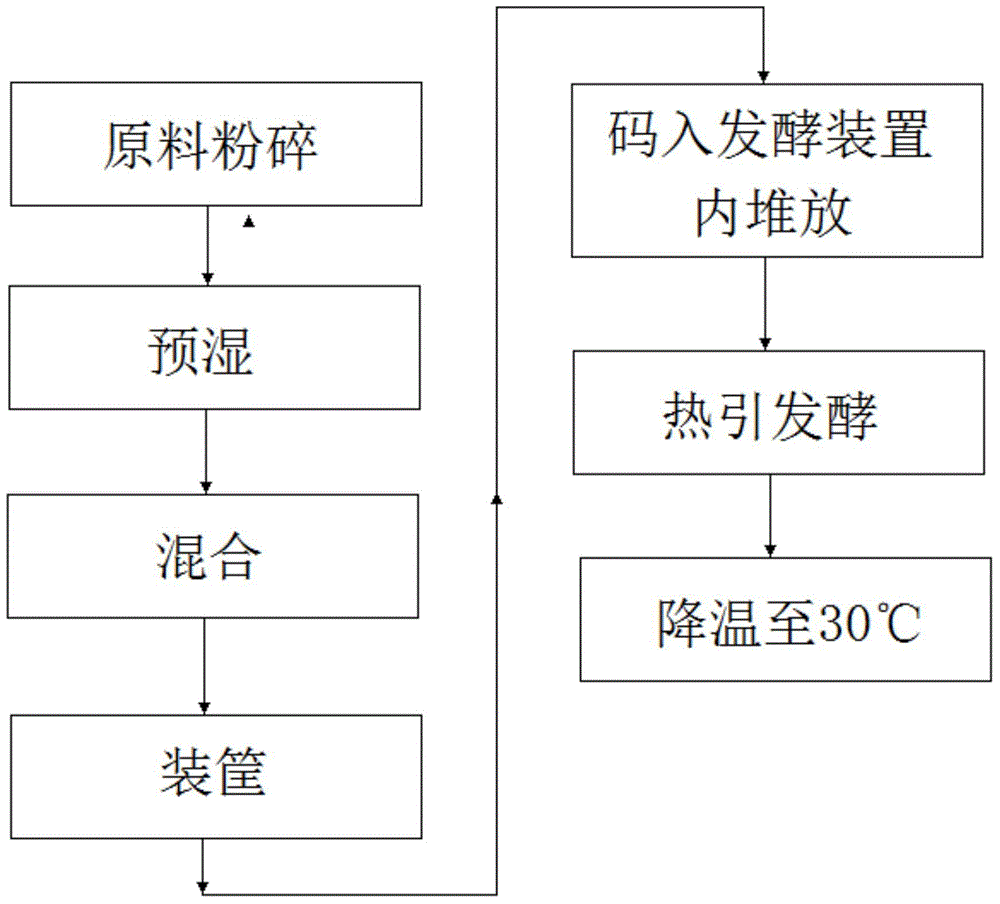

[0018] Such as figure 1 As shown, the production process of a new type of grass-rot edible fungus cultivation raw material includes: raw material crushing → pre-wetting → mixing → loading into baskets → stacking in the fermentation device → heat induction fermentation → cooling to 30 °C; the specific steps are as follows :

[0019] (1) Raw material crushing: the diameter of cow dung particles is less than 2cm, and the length of straw is less than 4cm. Straw with a relatively hard surface such as corn and sorghum needs to be chopped first and then crushed;

[0020] (2) Pre-wet: Soak the straw with 3% quicklime water for 5-7 days, add water to the cow dung until the water content is 65-70%, and stack it for 1-2 days; (strictly control the water content of raw materials, the specific value should be determined by the materials used);

[0021] (3) Mixing: mix cow dung and C with a blender a CO 3 , phosphate fertilizer, and gypsum, and then use a mixer to mix with straw, and add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com