A kind of preparation method of chalcogenide glass optical fiber

A chalcogenide glass and optical fiber technology, applied in glass manufacturing equipment, glass production, manufacturing tools, etc., can solve the problems of low thermal stability of chalcogenide glass, high optical fiber devitrification loss, limited capacity of glass material, etc., and achieve concentricity High, low fiber loss, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

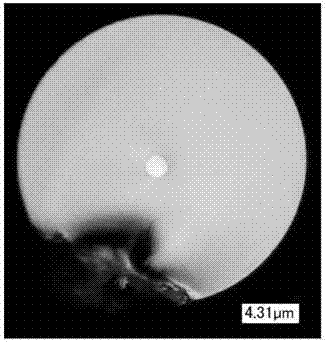

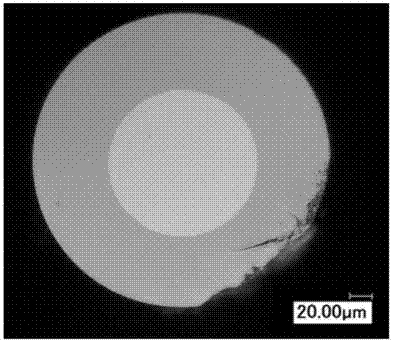

Image

Examples

Embodiment 1

[0027] A method for preparing a chalcogenide glass optical fiber, specifically comprising the following steps:

[0028] (1) Preparation of core layer and cladding glass

[0029] A. The cladding chalcogenide glass raw material and the core layer chalcogenide glass raw material are accurately weighed and put into quartz tubes respectively, and the two quartz tubes are vacuumed separately, and the vacuum degree reaches 3×10 -4 After pa, the quartz tube was sealed with a hydrogen-oxygen flame; the sealed quartz tube was placed in a swing furnace at 900°C for 8 hours, and the temperature of the swing furnace was lowered to 650°C. Take it out from the swing furnace for quenching and cooling until the surface of the glass melt is separated from the inner wall of the quartz tube; the length of the quartz tube is 400mm, the diameter of the quartz tube for placing the cladding chalcogenide glass raw material is 30mm, and the diameter of the quartz tube for placing the core layer chalco...

Embodiment 2

[0039] With above-mentioned embodiment 1, its difference is:

[0040] Step (1) During the preparation of the core layer and cladding glass: the vacuum degree of the quartz tube is controlled to 6×10 -4 pa; put the sealed quartz tube into a swinging furnace at 950°C for 6 hours, and then take the quartz tube out of the swinging furnace to quench the temperature after the temperature of the swinging furnace drops to 700°C; The melt is immediately placed in a precision annealing furnace at 30°C lower than the cladding glass transition temperature (Tg) for 6 hours, and then cooled down to room temperature at a rate of 5°C / h; Glass transition temperature (Tg) 30 ℃ precision annealing furnace keep warm for 6 hours and then drop to room temperature at a cooling rate of 5 ℃ / h; the length of the quartz tube is 800 mm, and the diameter of the quartz tube for placing the clad chalcogenide glass raw material is 40 mm. The diameter of the quartz tube for placing the core chalcogenide glas...

Embodiment 3

[0046] With above-mentioned embodiment 1, its difference is:

[0047] Step (1) During the preparation of the core layer and cladding glass: the vacuum degree of the quartz tube is controlled to 4.5×10 -4 pa; put the sealed quartz tube into a swing furnace at 925°C for 7 hours, and then take out the quartz tube from the swing furnace to quench the temperature after the temperature of the swing furnace drops to 675°C; The melt is immediately placed in a precision annealing furnace at 20°C lower than the cladding glass transition temperature (Tg) for 5 hours, and then cooled down to room temperature at a rate of 7.5°C / h; Glass transition temperature (Tg) 20 ℃ precision annealing furnace keep warm for 5 hours and then drop to room temperature at a cooling rate of 7.5 ℃ / h; the length of the quartz tube is 600 mm, and the diameter of the quartz tube for placing the clad chalcogenide glass raw material is 50 mm. The diameter of the quartz tube for placing the core layer chalcogenide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com