Hydraulic retarder control system and control method

A hydraulic retarder and control system technology, applied in hydraulic brakes, brake types, mechanical equipment, etc., can solve the problems of brake lining wear, threatening driving safety, shortening brake life, etc., achieving high reliability, Easy to operate, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

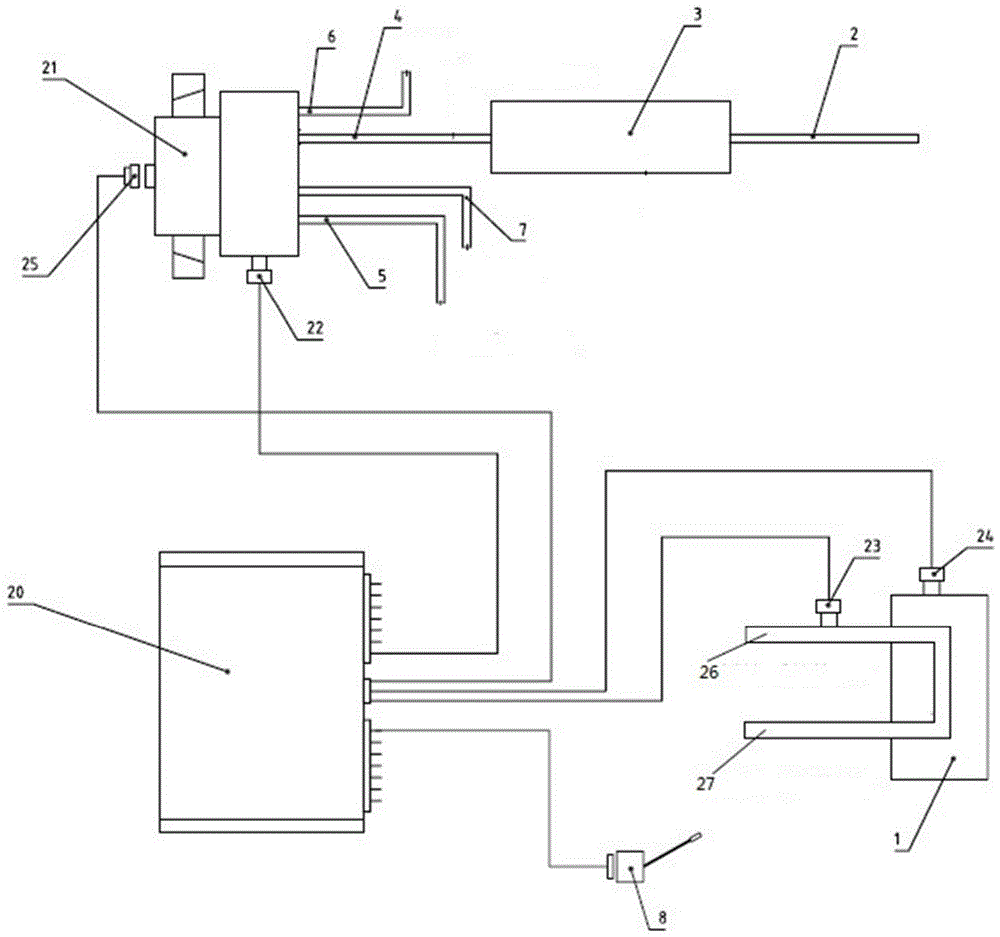

[0023] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

[0024] The control system of the hydraulic retarder includes an electromagnetic directional valve 21, a hydraulic retarder step switch 8, a control box 20, a compressed air pipeline, a vehicle auxiliary load air chamber 3, and a heat exchanger 1; the control box 20 is connected to the liquid The step switch 8 of the force retarder, the step switch 8 provides a working signal to the control box 20; the electromagnetic directional valve 21 is connected to the control box 20 through the electromagnetic directional valve current connection 25, and the control box 20 is connected to the electromagnetic directional valve 21 issues a control command; the electromagnetic reversing valve 21 is connected to the compressed air pipeline.

[0025] The compressed air pipeline includes a first compressed air pipeline 4 connected to the vehicle auxiliary load air chamber 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com