Automatic mold adjusting method and tyre vulcanizer

An automatic adjustment and curing machine technology, applied to tires, other household appliances, household appliances, etc., can solve the problems of increasing the overall curing time of the tire, increasing the pre-vulcanization preparation work, reducing the production efficiency, etc., to save the mold change operation time, The effect of reducing die change process steps and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

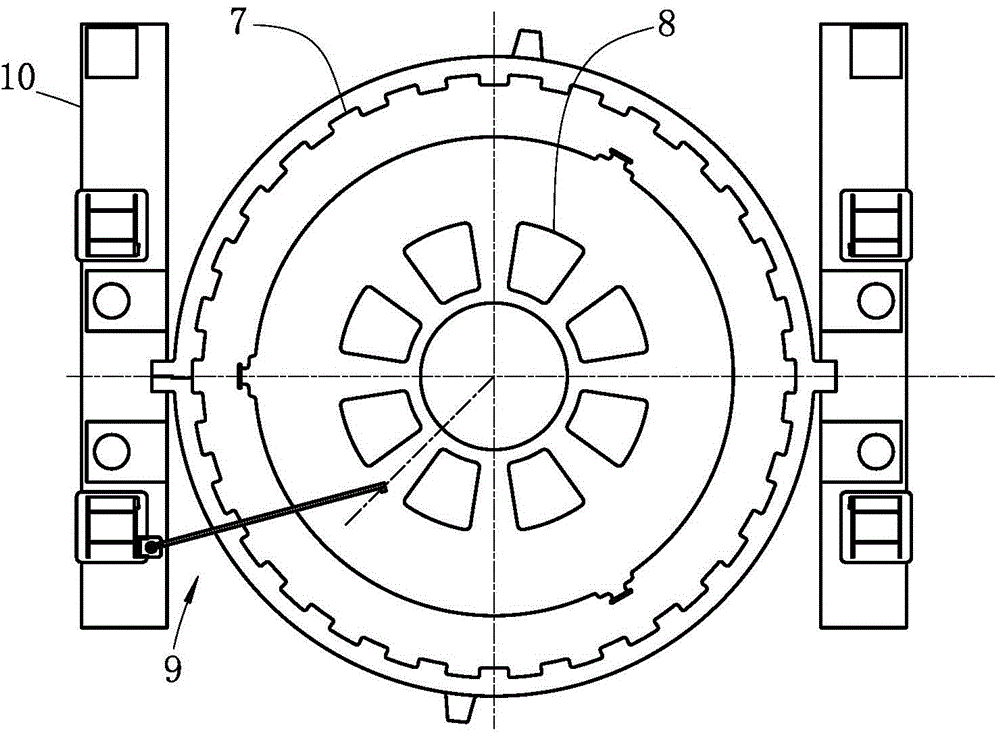

[0031] Such as Figure 1 to Figure 6 Commonly shown, the present invention provides a kind of automatic mold adjustment method, under the mold adjustment state, comprises the following steps: (a) set standard mold height value H in the control unit of vulcanizer, this standard mold height value H is The distance from a fixed height position on the vulcanizing machine to the upper side plate of the standard mold; (b) replace the tire and change the mold; (c) measure the actual height value H1 from the fixed height position to the upper side plate of the replaced tire mold, and compare the actual The height value H1 is transmitted to the control unit; (d) H1 is compared with H, the control unit drives the afterburner cylinder to drive the tire mold to move, and the moving distance ΔH=|H-H1|, where |H-H1| is the height of H and H1 The absolute value of the value difference, if H1>H, then the piston rod of the afterburner cylinder will be stretched out, and the tire mold will be m...

Embodiment 2

[0036] Such as Figure 1 to Figure 6 Commonly shown, the present invention provides an automatic mold adjustment method, which is basically the same as Embodiment 1, the difference is that a blind hole 305 is provided on the piston rod 303 of the booster cylinder 3, and the blind hole 305 is located at the bottom of the booster cylinder 3 On one side of the rodless cavity, the displacement sensor 307 is installed on the cylinder body 301 of the booster cylinder 3 and extends into the blind hole 305. The piston rod 303 of the booster cylinder 3 is provided with an induction ring 304, and the induction ring 304 and the displacement sensor 307 The displacement sensor 307 can sense the position of the piston rod 303 accurately. In order to improve the measurement accuracy of the displacement sensor 307 and prevent the interference caused by the flow of hydraulic oil, the piston rod 303 of the booster cylinder 3 is provided with an extension 306, and the extension 306 is slidably i...

Embodiment 3

[0038] Such as Figure 1 to Figure 6 As shown together, the present invention also provides a tire vulcanizing machine, which uses the automatic mold adjustment method in the above-mentioned embodiment 1 or embodiment 2.

[0039] Take the upper cover translational vulcanizing machine as an example to introduce the working principle of the automatic mold adjustment device:

[0040] The main components of the tire vulcanizing machine are: a base 2 installed on the foundation 1, on both sides of the base 2 on the foundation 1 there are slide rails 4, and a frame 10 driven by a hydraulic cylinder is slidably installed on the slide rails 4, The frame 10 is generally a gantry structure and moves in parallel on the slide rails 4. The frame 10 is provided with an upper cover 11 driven by a lifting mechanism. The lifting mechanism usually uses a hydraulic cylinder. A steam chamber 6 is arranged above the base 2, and the steam A support plate 5 is slidingly installed in the chamber 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com