Control method for preventing telescopic discharged hot-rolled pipeline steel coils

A steel unloading tower and control method technology, applied in the field of metallurgy, can solve the problems of the appropriate height of the unloading trolley and the inability to completely ensure the expansion and contraction of the mandrel, and achieve the appropriate height of the contact coil, reasonable diameter, and reduce the shape of the unloading tower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

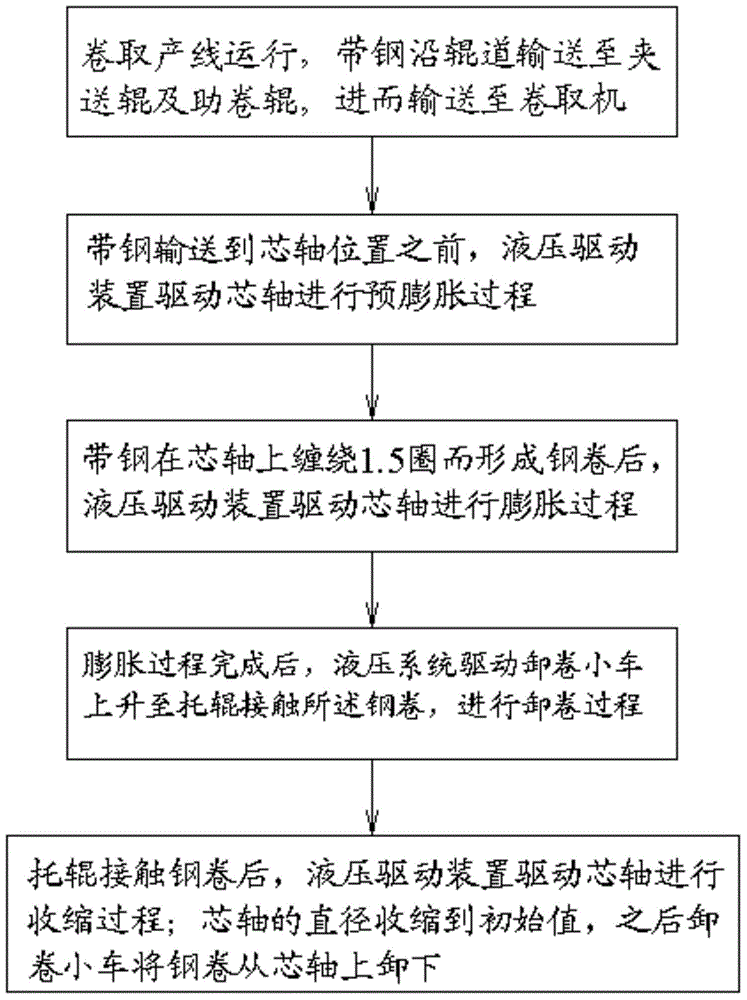

[0047] S1: The coiling production line is in operation, and the strip is conveyed along the roller table to the pinch roller and the auxiliary coiling roller, and then conveyed to the coiler.

[0048] S2: Before the steel strip is conveyed to the position of the mandrel, the hydraulic drive device drives the mandrel to perform the pre-expansion process; the control system controls the opening range of the expansion-contraction proportional valve to 97%; the control system controls the pressure value of the expansion-contraction hydraulic pressure relief valve The range is 115bar; the control system sets the number of winding turns of the strip on the mandrel as 1.5 turns; the diameter of the mandrel expands from the initial value to the pre-expansion value during the pre-expansion process, the initial value is 724mm, and the range of the pre-expansion value is 745mm .

[0049] S3: After the steel strip is wound on the mandrel for 1.5 turns to form a steel coil, the hydraulic d...

Embodiment 2

[0053] S1: The coiling production line is in operation, and the strip is conveyed along the roller table to the pinch roller and the auxiliary coiling roller, and then conveyed to the coiler.

[0054] S2: Before the steel strip is conveyed to the position of the mandrel, the hydraulic drive device drives the mandrel to carry out the pre-expansion process; the control system controls the opening range of the expansion-contraction proportional valve to 98%; the control system controls the pressure value of the expansion-contraction hydraulic pressure relief valve The range is 120bar; the control system sets the number of winding turns of the strip on the mandrel as 1.5 turns; the diameter of the mandrel expands from the initial value to the pre-expansion value during the pre-expansion process, the initial value is 724mm, and the range of the pre-expansion value is 748mm .

[0055] S3: After the steel strip is wound on the mandrel for 1.5 turns to form a steel coil, the hydraulic...

Embodiment 3

[0059] S1: The coiling production line is in operation, and the strip is conveyed along the roller table to the pinch roller and the auxiliary coiling roller, and then conveyed to the coiler.

[0060] S2: Before the steel strip is conveyed to the position of the mandrel, the hydraulic drive device drives the mandrel to perform the pre-expansion process; the control system controls the opening range of the expansion-contraction proportional valve to 99%; the control system controls the pressure value of the expansion-contraction hydraulic pressure relief valve The range is 125bar; the control system sets the number of winding turns of the strip on the mandrel as 1.5 turns; the diameter of the mandrel expands from the initial value to the pre-expansion value during the pre-expansion process, the initial value is 724mm, and the range of the pre-expansion value is 750mm .

[0061] S3: After the steel strip is wound on the mandrel for 1.5 turns to form a steel coil, the hydraulic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com