Equal-channel corner revolving extrusion die and method

A technology of equal channel corners and molds, applied in the field of material processing, can solve the problems of high equipment requirements, uneven deformation of forming materials, and inability to continuous production, and achieve the effects of simple mold structure, significant grain refinement, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

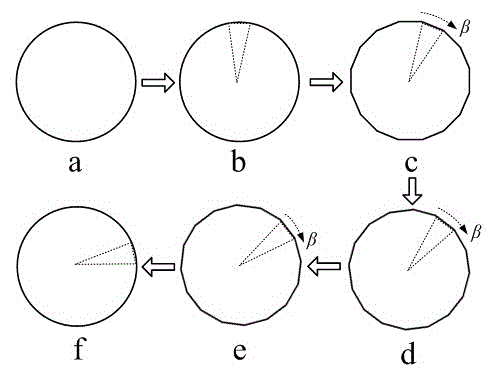

Image

Examples

Embodiment Construction

[0035] In this embodiment, the industrial pure copper with a diameter of 10 mm and a length of 25 mm is subjected to equal-channel rotational angle extrusion deformation by using the forming die and method of the present invention.

[0036] The equal-channel rotary extrusion mold used includes bolts 9 and valve molds 8. The parting surfaces of the two valve molds 8 are completely attached, and the center of the combined structure is the extrusion cavity of the mold. Bolt holes are respectively provided correspondingly, and the two are fastened by bolts 9; the extrusion die cavity is an equal-channel angular extrusion die cavity, and the equal-channel angular extrusion die cavity is sequentially provided with a die cavity introduction section 1, a die Cavity lead-in transition section 2, mold cavity corner section 3, mold cavity lead-out transition section 4, mold cavity lead-out section 5, and mold cavity take-out section 6;

[0037] The mold cavity introduction section 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com