Efficient fine crusher

A fine crusher and high-efficiency technology, applied in grain processing and other directions, can solve problems such as the inability to meet the requirements of product production, and achieve the effects of being conducive to crushing, increasing the number of collisions, and speeding up the rotation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

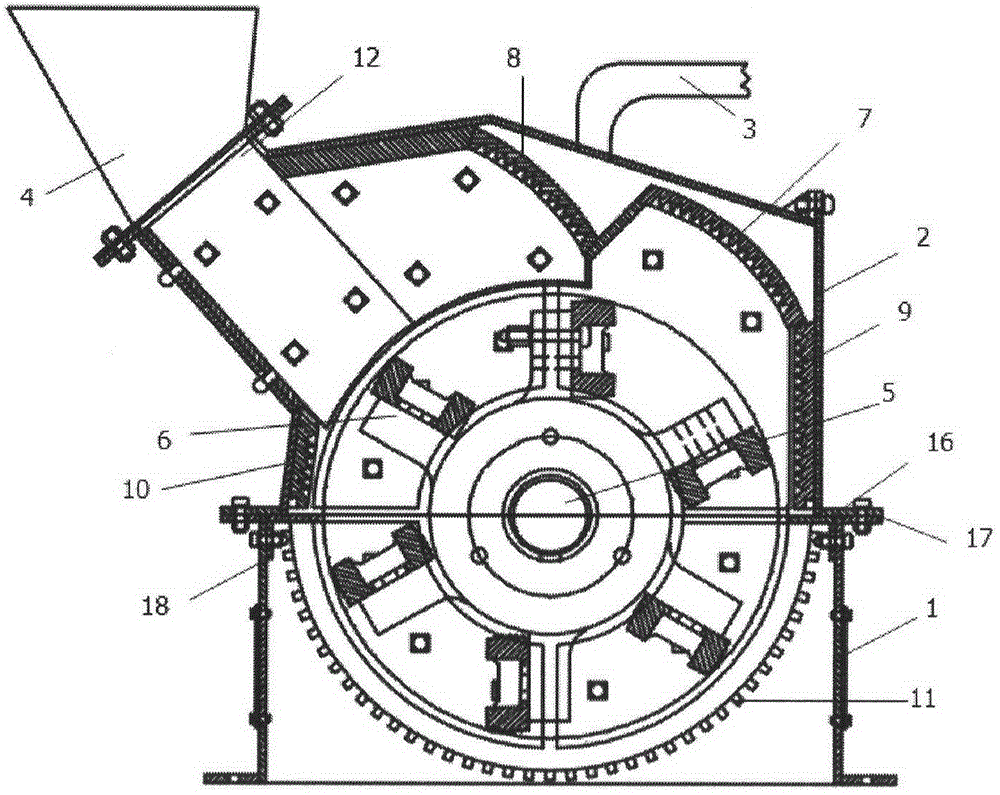

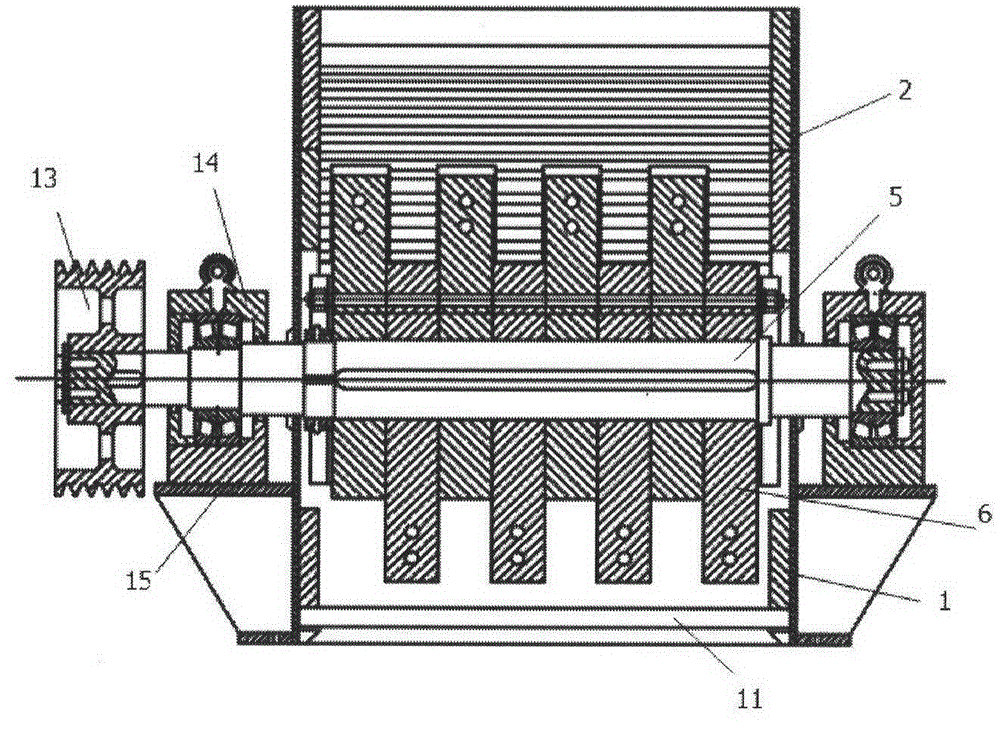

[0020] Such as figure 1 and figure 2 As shown, the high-efficiency fine crusher of the present invention includes a lower housing 1, an upper housing 2 located above the lower housing 1, a feed hopper 4 located at the upper left of the upper housing 2, a The rotating shaft 5 inside the lower housing 1, the crushing hammer 6 connected to the rotating shaft 5, a number of counter-attack plates located around the crushing hammer 6, several strips 11 located below the crushing hammer 6, support the rotating shaft 5 and the drive wheel 13 that drives the rotating shaft 5 to rotate.

[0021] Such as figure 1 and figure 2 As shown, the lower casing 1 is in the shape of a cuboid, and a support platform 15 is respectively provided on the front and rear surfaces of the lower casing 1 , and one end of the support platform 15 is fixedly connected with the surface of the lower casing 1 . The upper end of the lower casing 1 extends outward to form a first horizontal portion 17 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com