Free trajectory gluing device of toe lasting machine

A technology of gluing device and front upper machine, which is applied in the direction of shoemaking machinery, clothing, and gluing shoe parts, etc. It can solve the problems of complex shoe shape process, difficult to guarantee the quality of gluing, unilateral glue leakage, etc., and achieve a solution Glue leakage and unfit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

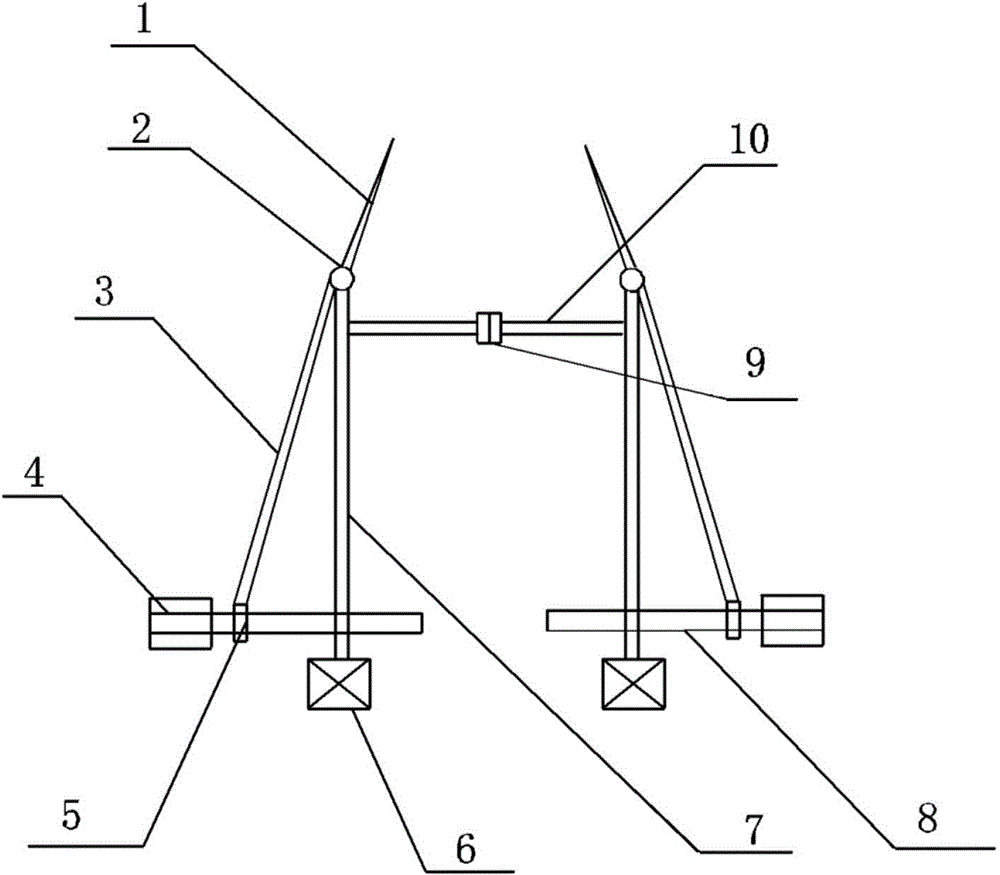

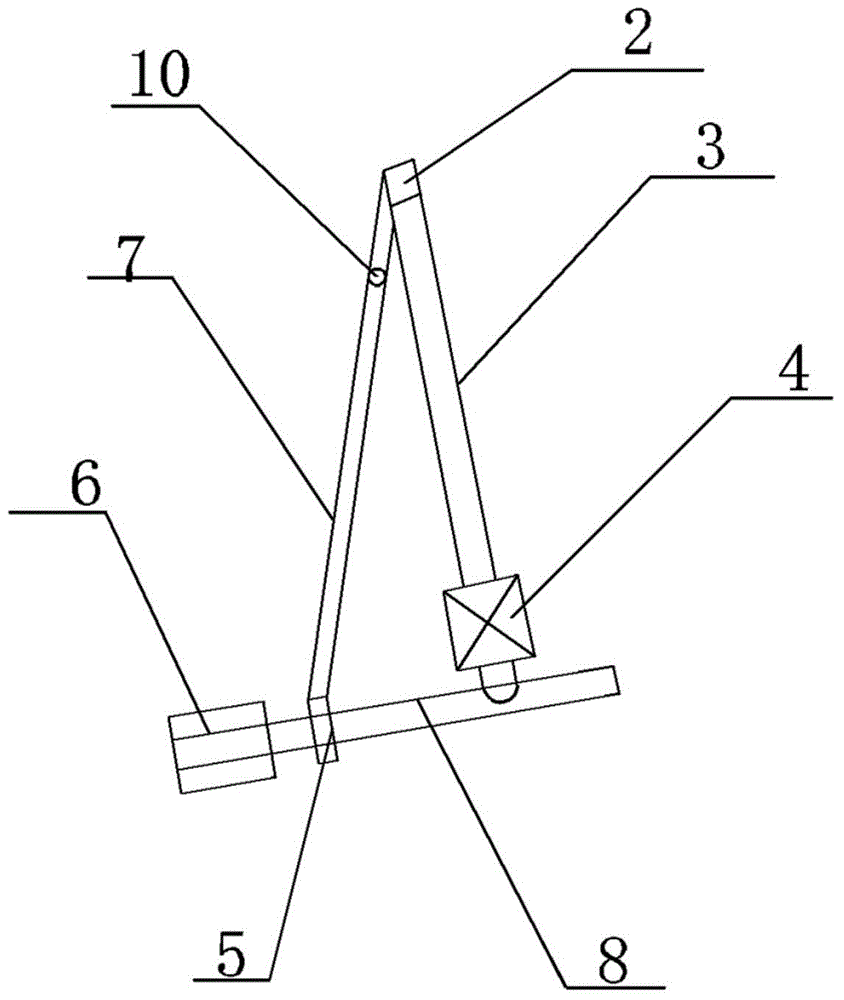

[0012] A free-track gluing device for a front end machine, including two left and right glue nozzles 1, X-axis and Y-axis servo motors, two sets of swing levers in the X-axis and Y-axis, and X-axis and Y-axis rotating shafts , ball screw 8 and ball sliding nut 5, the servo motors are respectively 2 in the X-axis and Y-axis directions, and the ball screw 8 at the head of each X-axis servo motor 6 is covered with a ball sliding nut 5, The ball sliding nut 5 is connected to one end of the X-axis swing rod 7, the other end of the X-axis swing rod 7 is connected to the X-axis shaft 10, and extends to the Y-axis shaft 2, and each Y-axis servo motor 4 The ball screw 8 on the head is covered with a ball sliding nut 5, the ball sliding nut 5 is connected to one end of the Y-axis swing rod 3, and the other end of the Y-axis swing rod 3 is connected to the Y-axis shaft 2, and the Y-axis The swinging rod 3 and the X-axis swinging rod 7 meet at the Y-axis rotating shaft 2 and control the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com