Decoupling control method and system for temperature field regional control system

A partition control and decoupling control technology, which is applied in the direction of temperature control using electric mode, auxiliary controller with auxiliary heating device, etc., can solve problems such as difficult decoupling and complex decoupling algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

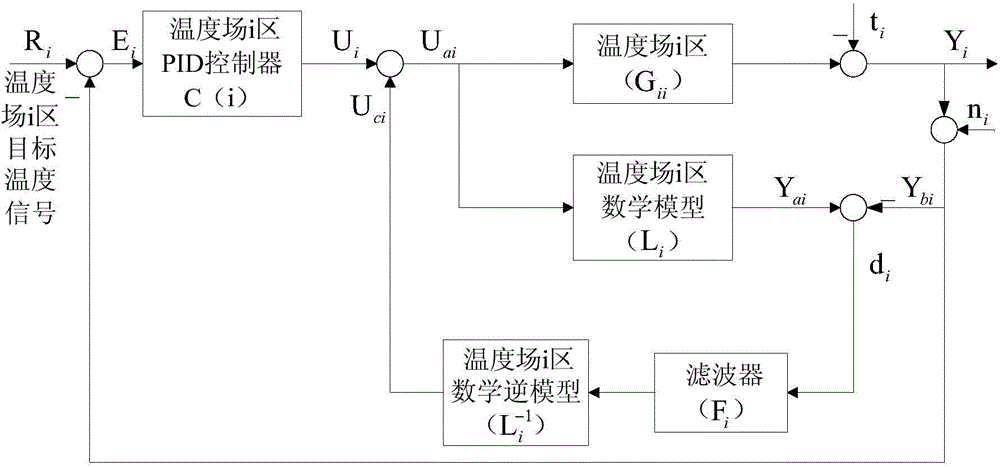

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] In order to apply the method and system for decoupling control of the temperature field partitions proposed in the present invention, a chip curing furnace is selected as a specific implementation object. There are often several heating plates in the actual chip curing furnace, and each heating plate corresponds to a temperature zone, and they affect each other. For a certain point on the substrate, its temperature is the superposition result of the thermal effects of multiple heating plates. , it is difficult to precisely control the temperature, thus affecting the quality of chip curing. It can be seen that there is strong coupling between the temperature fields in the chip curing furnace, and decoupling control is required.

[0033] Such as figure 1 As shown, it is a schematic diagram of the hardware connection to realize the decoupling cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com