Infrared stealth thin film with spectral selectivity and low emission rate and preparation method of infrared stealth thin film

A low-emissivity and selective technology, applied in the field of infrared stealth films and their preparation, can solve problems such as low emissivity, and achieve the effects of small residual thermal stress, good thermal matching, and not easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

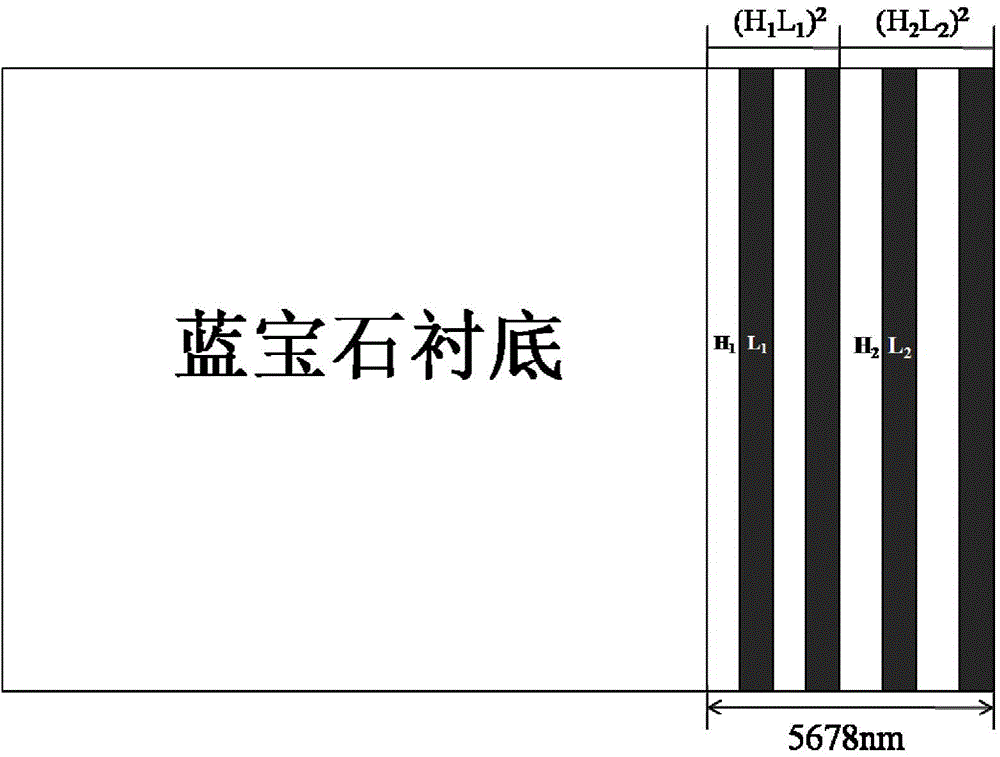

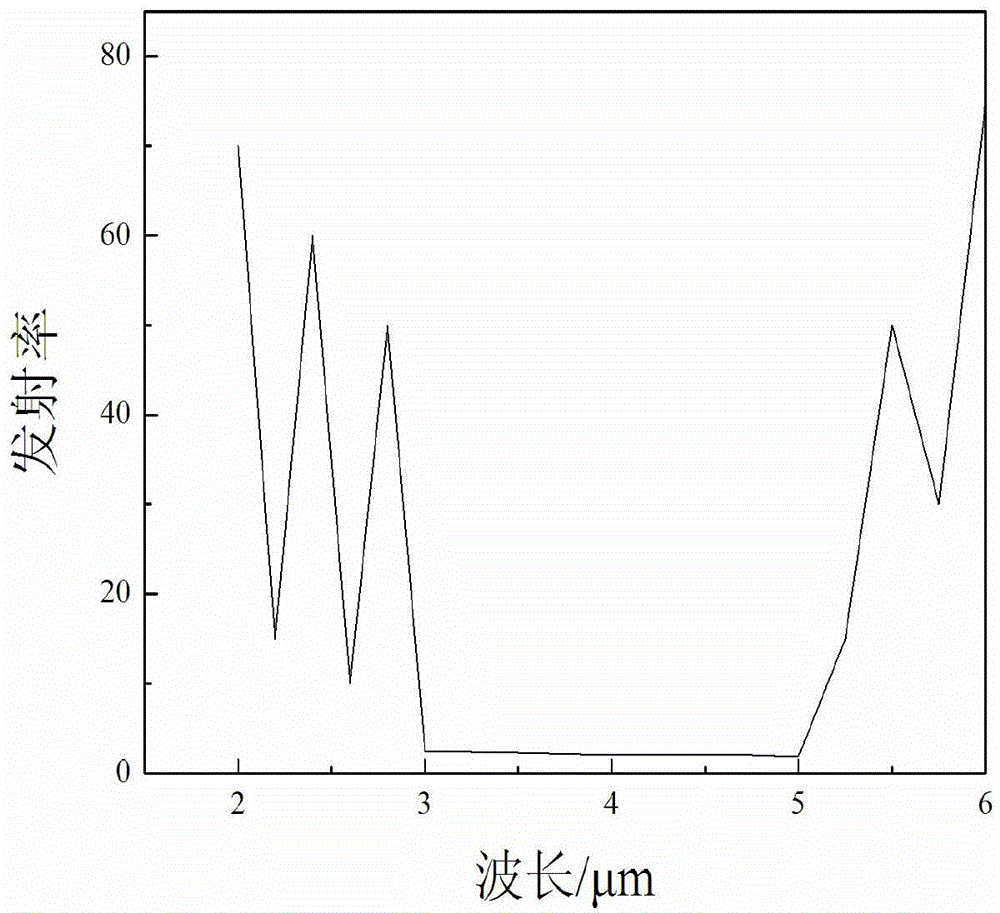

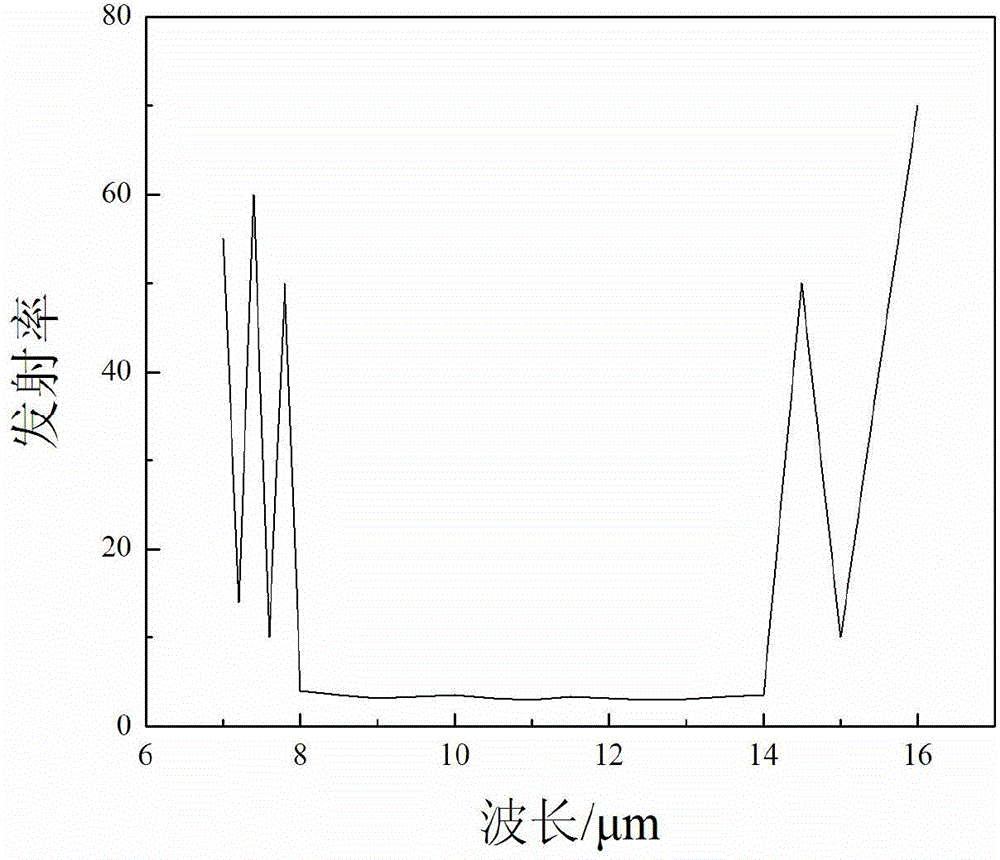

[0036] a kind of like figure 1 Shown is an infrared stealth film with spectral selectivity and low emissivity. The infrared stealth film is a film that can regulate the emitted radiation of the spectrum, and its substrate is sapphire. The infrared stealth film is a multi-layer stacked structure, and the multi-layer stacked structure includes a periodic stacked structure composed of layers of high-refractive-index materials and layers of low-refractive-index materials; the periodic stacked structure includes a composite stacked first A multilayer film structure and a second multilayer film structure, the central wavelength of the first multilayer film structure is λ 1 , the central wavelength of the second multilayer film structure is λ 2 , and λ 1 = 4.0 μm, λ 2 = 11.0 μm. The layers are connected by chemical bonding.

[0037] In the infrared stealth film with spectral selectivity and low emissivity of this embodiment, the high refractive index material layer is a Si mater...

Embodiment 2

[0045] An infrared stealth film with spectral selectivity and low emissivity according to the present invention, the infrared stealth film is a film capable of regulating the emitted radiation of the spectrum, and its substrate is sapphire. The infrared stealth film is a multi-layer stacked structure, and the multi-layer stacked structure includes a periodic stacked structure composed of layers of high-refractive-index materials and layers of low-refractive-index materials; the periodic stacked structure includes a composite stacked first A multilayer film structure and a second multilayer film structure, the central wavelength of the first multilayer film structure is λ 1 , the central wavelength of the second multilayer film structure is λ 2 , and λ 1 = 4.0 μm, λ 2 = 11.0 μm. The layers are connected by chemical bonding.

[0046] In the infrared stealth film with spectral selectivity and low emissivity of this embodiment, the high refractive index material layer is a Si ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com