Dielectric substrate measurement apparatus based on multi-resonant waveguide substrate integration vibration cavity method and method thereof

A technology of substrate integration and dielectric substrate, which is applied in measurement devices, measurement of electrical variables, measurement of resistance/reactance/impedance, etc., can solve the problem of inability to realize fast broadband test, and achieve simple design, convenient processing, and quality factor. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

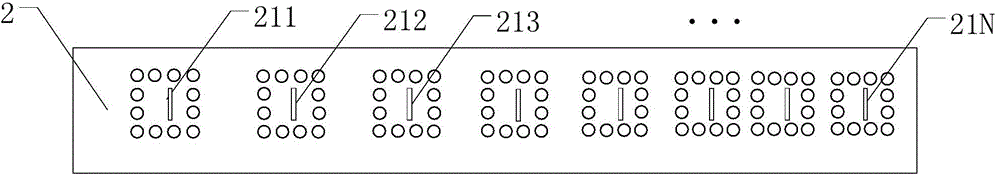

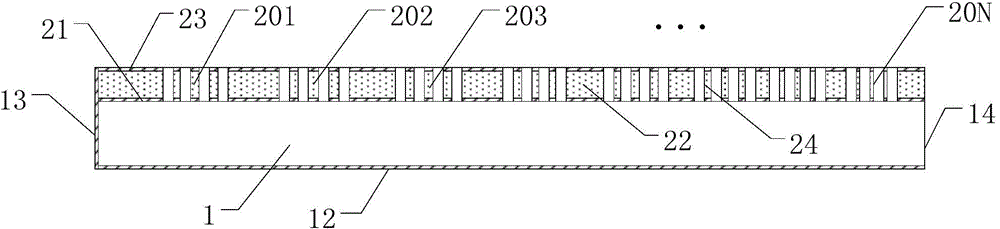

[0030] Substrate-integrated waveguide multi-resonator, including multiple resonators 2 and standard W-band metal feed waveguide 1, the design feature of resonator 2 is that, viewed from left to right, 201-20N are N substrate-integrated waveguide resonators . The resonant cavity 201-20N is viewed as a square from the top view. In order to satisfy the resonant frequency with a fixed frequency interval, the size of the 201-20N gradually decreases. The initial value of the design size can be determined according to the HFSS eigenmode simulation. The resonant cavity 2 includes, from top to bottom, an upper metal-clad copper 23, a dielectric 22, a lower metal-clad copper 21, and a metallized hole 24 that runs through the upper metal-clad copper 23, the dielectric 22, and the metal-clad copper 21. 211-21N are The coupling slots on the copper-cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com