Method for measuring liquid viscosity by utilization of capillary and device used for method

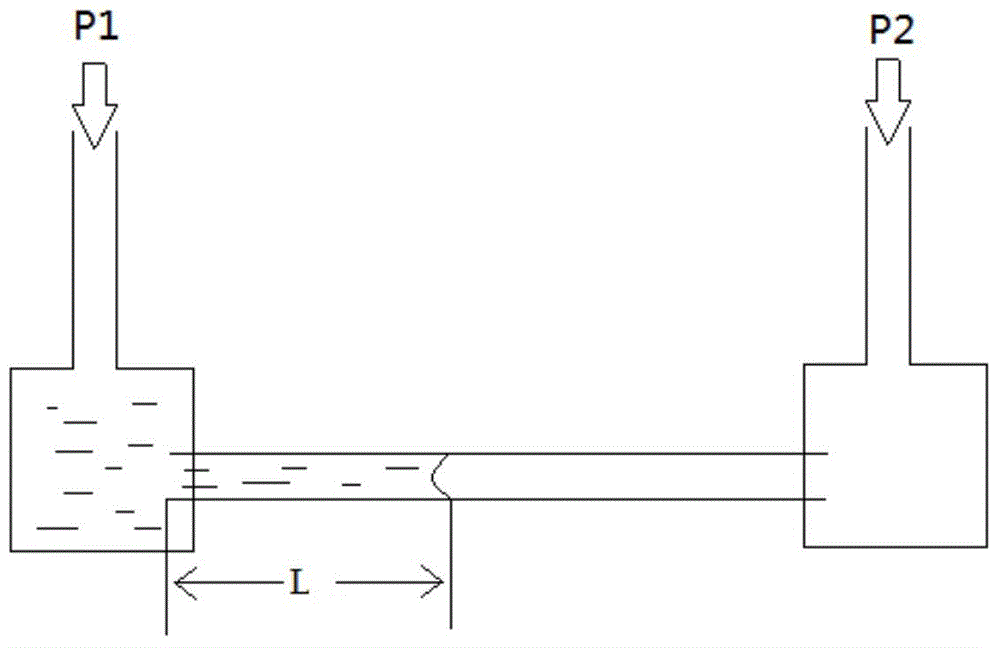

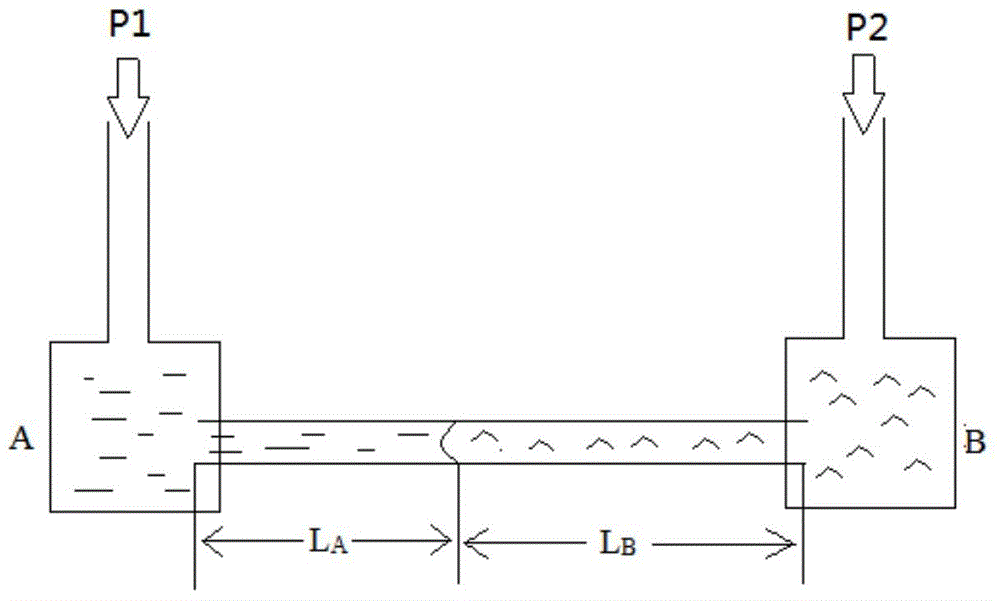

A capillary, liquid technology, applied in the field of analytical chemistry, can solve the problems of only being affected by gravity, calculating the liquid flow rate, and cannot change the pressure, etc., to achieve the effect of reliable results, easy data acquisition, and simple calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] At temperature T=25.3°C, in a capillary with an inner diameter of 1.7 μm (radius of 0.85 μm) and a total length of L=178 mm, the length of the water column L w =38mm, the measured v(ΔP) relationship line is v=2.41ΔP+406, and the slope of the line is k=2.41μm·s -1 kPa -1 , then the viscosity η of water w =0.85 2 / (8×2.41×38)=0.99×10 -3 Pa·s; water column length L w When =68mm, the measured v(ΔP) relationship line is v=1.362ΔP+217, and the slope of the line is k=1.362μm·s -1 kPa -1 , then the viscosity η of water w =0.85 2 / (8×1.362×68)=0.98×10 -3 Pa·s; water column length L w When =88mm, the measured v(ΔP) relationship line is v=0.967ΔP+166, and the slope of the line is k=0.967μm·s -1 kPa -1 , then the viscosity η of water w =0.85 2 / (8×0.967×88)=1.06×10 -3 Pa s; then in a capillary with an inner diameter of 1.7 μm, the viscosity of water is η w =(0.99×10 -3 Pa·s+0.98×10 -3 Pa·s+1.06×10 -3 Pa·s) / 3=1.01×10 -3 Pa·s.

Embodiment 2

[0042] When the temperature T=24.6°C, the inner diameter is 11.26 μm (the radius is 5.63 μm), in the capillary of total length L=181mm, the liquid column length L of 65% by weight glycerol (glycerol, the same below) aqueous solution g When =50mm, the measured v(ΔP) relationship line is v=3.64ΔP+100, and the slope of the line is k=3.64μm·s -1 kPa -1 , then the viscosity η of 65% glycerol aqueous solution g =5.63 2 / (8×3.64×50)=21.8×10 -3 Pa·s; 65% glycerin aqueous solution liquid column length L g =80mm, the measured v(ΔP) relationship line is v=2.30ΔP+62.8, and the slope of the line is k=2.30μm·s -1 kPa -1 , then the viscosity η of 65% glycerol aqueous solution g =5.63 2 / (8×2.30×80)=21.5×10 -3 Pa·s; 65% glycerin aqueous solution liquid column length L g =110mm, the measured v(ΔP) relationship line is v=1.64ΔP+43.5, and the slope of the line is k=1.64μm·s -1 kPa -1 , then the viscosity η of 65% glycerol aqueous solution g =5.63 2 / (8×1.64×110)=22.0×10 -3 Pa s; th...

Embodiment 3

[0044] At temperature T=25.8°C, in a capillary with an inner diameter of 205 μm (radius of 102.5 μm) and a total length of L=178 mm, the liquid column length L of 99% by weight glycerin aqueous solution g When =57mm, the measured v(ΔP) relationship line is v=33.18ΔP+43.25, and the slope of the line is k=33.18μm·s -1 kPa -1 , then the viscosity η of 99% glycerol aqueous solution g =102.5 2 / (8×33.18×57)=0.694Pa·s; 99% glycerin aqueous solution liquid column length L g When =77mm, the measured v(ΔP) relationship line is v=24.57ΔP+30.99, and the slope of the line is k=24.57μm·s -1 kPa -1 , then the viscosity η of 99% glycerol aqueous solution g =102.5 2 / (8×24.57×77)=0.694Pa·s; 99% glycerin aqueous solution liquid column length L g =97mm, the measured v(ΔP) relationship line is v=19.20ΔP+25.93, and the slope of the line is k=19.20μm·s -1 kPa -1 , then the viscosity η of 99% glycerol aqueous solution g =102.5 2 / (8×19.20×97)=0.705Pa s; then in a capillary with an inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com