Yaw Control System And Yaw Control Method For Wind Turbine Generator

A wind power generation device and yaw control technology, which is applied in the field of yaw control system, can solve problems such as cable damage or cutting, deterioration of the operating rate of wind power generation devices, and inability to detect the yaw direction value, etc., to achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, dimensions, materials, shapes, relative arrangements, and the like of components described below or shown in the drawings as embodiments do not limit the scope of the present invention, but are merely illustrative examples.

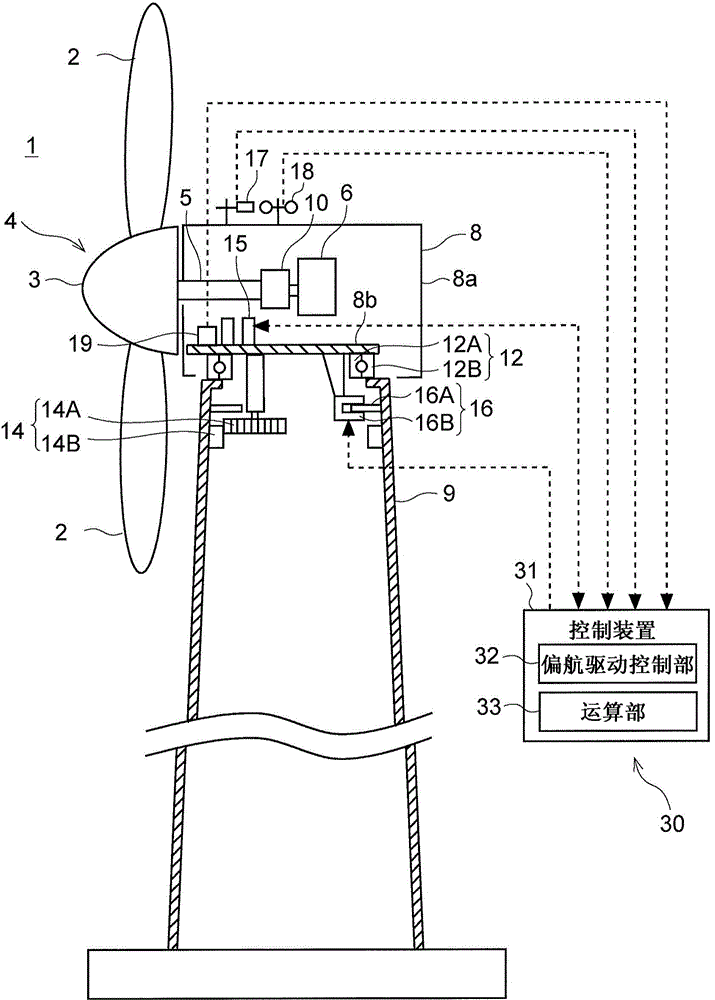

[0092] First, refer to figure 1 , a configuration example of the wind power generator 1 and the yaw control system 30 according to the embodiment of the present invention will be described. It should be noted, figure 1 It is a side view showing a schematic overall configuration of a wind power generator 1 according to one embodiment.

[0093] In several embodiments, figure 1 In the wind power generator 1 shown, a rotor 4 including at least two blades 2 and a hub 3 is rotated by wind energy. The hub 3 can be formed in one piece from a casting, with mountings for the blades 2 . For example, the wind power generator 1 may have a structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com