Method for improving downhole heating coal seam gas extraction amount

A technology for coal seam gas and extraction volume, which is applied in the field of gas extraction in high-gas and low-permeability inclined coal seams, can solve the problems of complex operation process, poor safety and high cost, and achieves simple operation process, easy acquisition and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

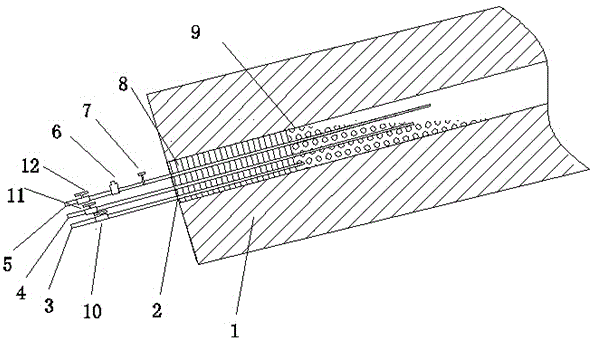

[0018] An example of the present invention will be further described below in conjunction with accompanying drawing:

[0019] As shown in the figure, firstly, a borehole 2 is constructed in the middle of the coal seam 1 with a diameter of Ф90-120mm. Then insert the grouting pipe 3, the grouting pipe 4 and the extraction pipe 5 in sequence into the borehole 2, wherein the front end of the grouting pipe 4 is 3~5m away from the front end of the grouting pipe 3, so as to avoid excessive grouting, and the front end of the extraction pipe 5 0.5 ~ 1.5m away from the front end of the slurry return pipe 4, which can save pipe material. Then inject polyurethane sealing agent 8 into the drill hole 2 where the grouting pipe 3, grout return pipe 4, and extraction pipe 5 are inserted, and pay attention to make the front end of the grouting pipe 3 exceed the front end of the polyurethane 8 by 10~30cm, so that the grout can be easily returned. The polyurethane sealing agent 8 is fully expand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com