A slip packer with hydraulic setting and rotary unsealing

A technology of slip packer and rotary unsealing, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc. It can solve the problem of large unsealing force, early unsealing of packers, and suspension capacity Poor and other problems, to achieve the effect of long-lasting and effective setting, simple and easy operation for unsealing, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

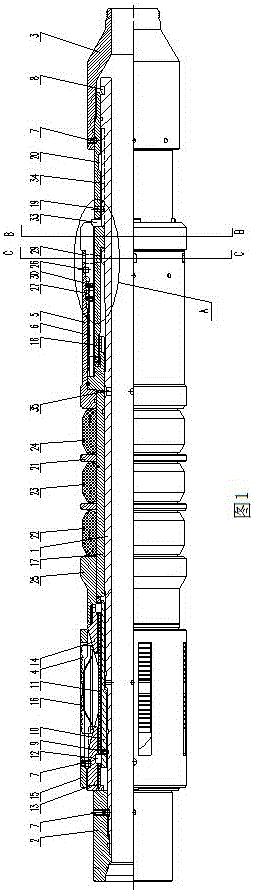

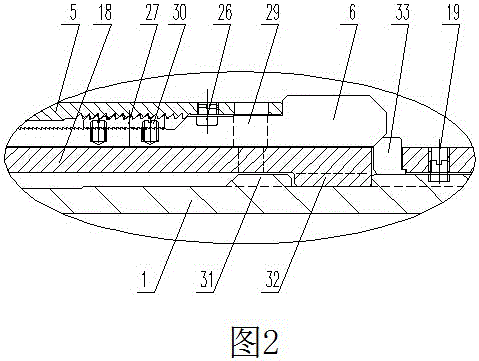

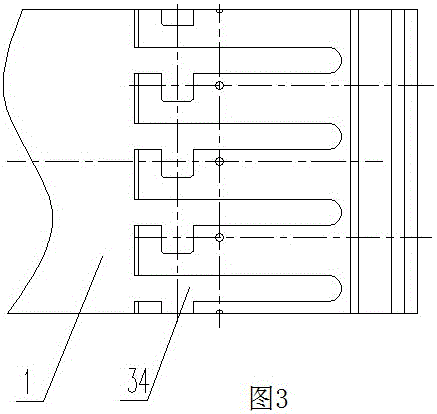

[0031] The slip packer with hydraulic setting and rotating unsealing includes a central pipe 1, an upper joint 2, a lower joint 3, a slip 4, a piston sleeve 5 and a release sleeve 6. An upper joint 2 is threadedly installed at one end of the center tube 1, and the center tube 1 and the upper joint 2 are fixed by a set screw 7. A C-ring 8 is installed at the other end of the center tube 1 through the assembly groove.

[0032] The inner sleeve 10 is installed on the center tube 1 on the side of the upper joint 2 through the shear pin A9; the inner sleeve 10 is clamped with the slip upper cone 13 and the card through the cone release shaft 11 and the symmetrically arranged key block A12 Tile under the cone 14. A slip 4 is installed between the slip upper cone 13 and the slip lower cone 14 through a slip sheath 15 and a leaf spring 16; the leaf spring 16 is connected with the upper cone 13 of the slip through a set screw 7.

[0033] A bushing 17 is installed on the central pipe 1 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com