Cinder concrete composite insulation non-dismantling fire-resistant mold plate and construction method thereof

A composite thermal insulation and construction method technology, applied in the field of construction, can solve the problems of safety loss of people's lives and property, difficult quality control, and fire of thermal insulation materials, and achieve the unique advantages of superior fire resistance, convenient and simple construction, and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

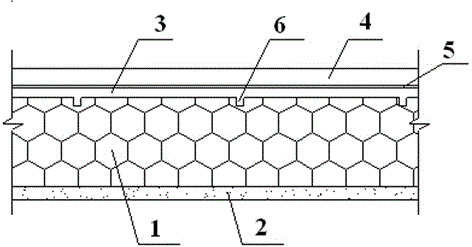

[0028] 1. If figure 1 As shown, a slag concrete composite thermal insulation non-demolition fireproof formwork, which includes a thermal insulation layer (1), an internal bonded fine slag mortar layer (2) bonded to the inner side of the thermal insulation layer (1), bonded to the thermal insulation layer (1) ) the outer bonded fine slag mortar layer (3) on the outer side, and the coarse slag concrete reinforcement layer (4) bonded on the outer bonded fine slag mortar layer (3);

[0029] Alkali-resistant mesh cloth (5) is provided between the outer bonded fine slag mortar layer (3) and the coarse slag concrete reinforcement layer (4); the inner bonded fine slag mortar layer (2) and the outer A mesh cloth is arranged inside the bonded fine slag mortar layer (3);

[0030] The thermal insulation layer (1) is polystyrene thermal insulation board or EPS polystyrene board or inorganic fireproof board.

[0031] In the above-mentioned slag concrete composite thermal insulation non-de...

Embodiment 2

[0040] Such as figure 2 As shown, the construction method of the slag concrete composite thermal insulation free fireproof formwork external thermal insulation wall includes the following steps:

[0041] a. Take the slag concrete composite thermal insulation non-demolition fireproof template A, and first drill anchor bolt holes on the slag concrete composite thermal insulation non-demolition fireproof template A;

[0042] b. When erecting concrete wall, beam or column formwork (7), insert the barbed anchor bolt connector (8) into the anchor bolt hole of the slag concrete composite thermal insulation non-demolition fireproof formwork A, the barbed anchor bolt The length of the connecting piece (8) is longer than the thickness of the slag concrete composite thermal insulation free fire prevention template A;

[0043] c. Then pour a concrete wall, beam or column (9) between the concrete wall, beam or column formwork (7) and the slag concrete composite thermal insulation free fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com