Environment-friendly sacrificial zinc alloy anode

A sacrificial anode and zinc alloy technology, which is applied in the field of corrosion and protection, can solve problems such as human respiratory tract and liver hazards, achieve the effects of lower melting temperature, wide application range, and reduced combustion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

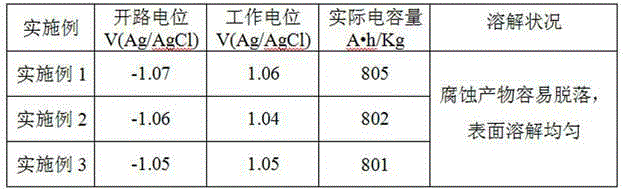

Embodiment 1

[0020] Zinc alloy sacrificial anode element weight percentage: Al: 0.33%, Mg: 0.78%, Ca: 0.022%, of which impurity elements Fe: 0.002%, Pb: 0.0028%, Cu: 0.0009%, Cd: 0.0015%, the balance is Zn .

[0021] Heat the 99.99 zinc ingot in the national standard GB / T 470-2008 to 480°C in a melting furnace to melt the zinc ingot completely, and add zinc-magnesium alloy, zinc-aluminum alloy and zinc-calcium alloy according to the ratio of the above components. Among them, the mass percentage content of magnesium in the zinc-magnesium alloy is 45%, the mass percentage content of aluminum in the zinc-aluminum alloy is 8%, and the mass percentage content of calcium in the zinc-calcium alloy is 55%. After the alloy addition is completed, cover the graphite layer on the zinc liquid, and at the same time pass nitrogen in the smelting furnace to evacuate the air and reduce the oxygen content, turn on the magnetic stirring to fully stir, and stir for 17 minutes to mix the alloy elements evenly....

Embodiment 2

[0023] The weight percentage of each component of the zinc alloy sacrificial anode: Al: 0.49%, Mg: 1.28%, Ca: 0.046%, of which impurity elements Fe: 0.0018%, Pb: 0.0022%, Cu: 0.0008%, Cd: 0.0018%, and the rest The amount is Zn.

[0024] Heat the 99.99 zinc ingot in the national standard GB / T 470-2008 to 470°C in a melting furnace to melt the zinc ingot completely, and then add zinc-magnesium alloy, zinc-aluminum alloy and zinc-calcium alloy according to the ratio of the above components. Among them, the mass percentage content of magnesium in the zinc-magnesium alloy is 48%, the mass percentage content of aluminum in the zinc-aluminum alloy is 15%, and the mass percentage content of calcium in the zinc-calcium alloy is 50%. After the alloy addition is completed, cover the graphite layer on the zinc liquid, and at the same time pass nitrogen in the smelting furnace to evacuate the air and reduce the oxygen content, turn on the magnetic stirring to fully stir, and stir for 15 mi...

Embodiment 3

[0026] The weight percentage of zinc alloy sacrificial anode: Al: 0.18%, Mg: 0.35%, Ca: 0.032%, of which impurity elements Fe: 0.0012%, Pb: 0.0039%, Cu: 0.0009%, Cd: 0.0021%, the balance is Zn .

[0027] Heat the 99.99 zinc ingot in the national standard GB / T 470-2008 to 460°C in a melting furnace to melt the zinc ingot completely, and add zinc-magnesium alloy, zinc-aluminum alloy and zinc-calcium alloy according to the ratio of the above components. Wherein the mass percentage content of magnesium in the zinc-magnesium alloy is 40%, the mass percentage content of aluminum in the zinc-aluminum alloy is 15%, and the mass percentage content of calcium in the zinc-calcium alloy is 58%. After the alloy addition is completed, cover the graphite layer on the zinc liquid, and at the same time pass nitrogen in the smelting furnace to evacuate the air and reduce the oxygen content, turn on the magnetic stirring and stir thoroughly, and stir for 12 minutes to mix the alloy elements even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com