Super-hydrophobic Ti-containing nanometer mordenite molecular sieve preparation method

A super-hydrophobic, nanowire technology, applied in the direction of crystalline aluminosilicate zeolite, etc., to achieve the effect of less pollution and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

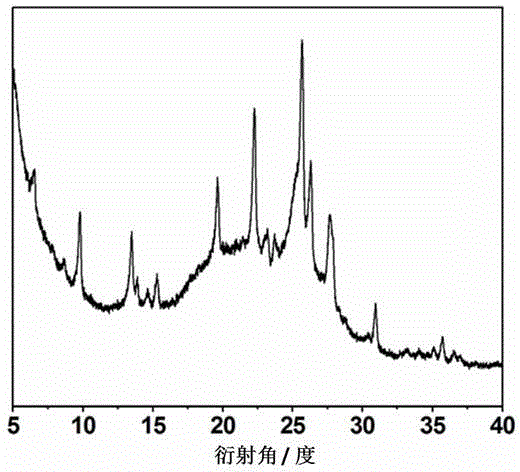

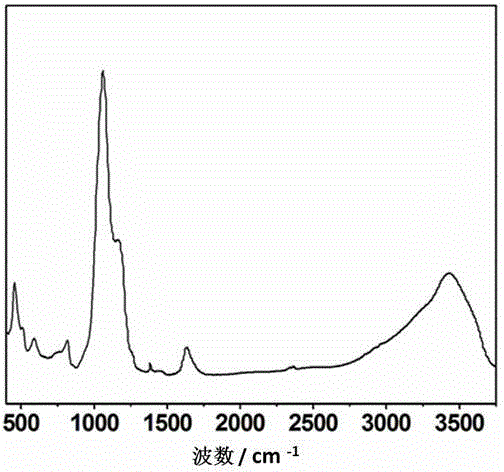

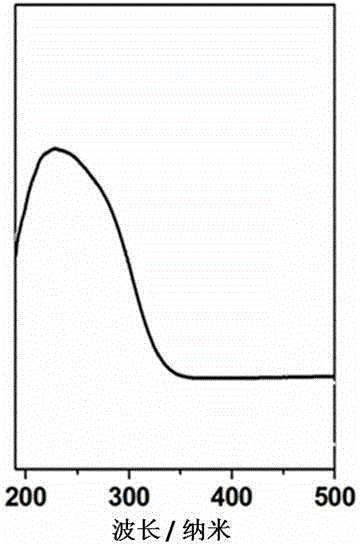

Image

Examples

Embodiment 1

[0028] Synthesis of nano-mordenite molecular sieves: 2.698 g CTATos and 80 g H 2 O mixed, heated in a constant temperature water bath at 60 ℃ for 2 h to form a solution A; another 2.107 g NaOH and 67.8 ml H 2 O mixed, stirred until clear liquid, added aluminum isopropoxide to it, and then heated in a constant temperature water bath at 60 °C for 1 h, after the aluminum isopropoxide was completely dissolved, slowly added 17.428 g of silica sol dropwise, and then Keep the original temperature constant, and continue to stir for 2 h to form B solution; finally, add B solution dropwise to A solution, continue to stir for 2 h, and transfer the mixture to a stainless steel static crystallization kettle lined with polytetrafluoroethylene and placed it in an oven at 130 °C for 5 days for crystallization, after conventional suction filtration, washing with deionized water, drying, and then roasting at 550 °C for 5 h to obtain mesoporous nano-mordenite molecular sieves. The initial molar...

Embodiment 2

[0033] Except changing the silylating agent in embodiment 1 into monomethylethoxysilane (CH 3 Si(OCH 2 CH 3 ) 3 ), other preparation conditions were the same as in Example 1, and titanium-containing nano-mordenite molecular sieves with different degrees of hydrophobicity were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com