A fast and fine-tuning track inspection instrument for measuring track geometric parameters

A technology of geometric parameters and inspection instrument, which is applied in railway vehicle shape measuring instrument, railway car body parts, railway auxiliary equipment, etc., can solve the problems of high detection efficiency, unattainable equipment, short skylight time, etc., to improve efficiency , Accurately measure the effect of continuous, easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the fast and fine-tuning track inspection instrument for track geometric parameter measurement will be described below with reference to the accompanying drawings.

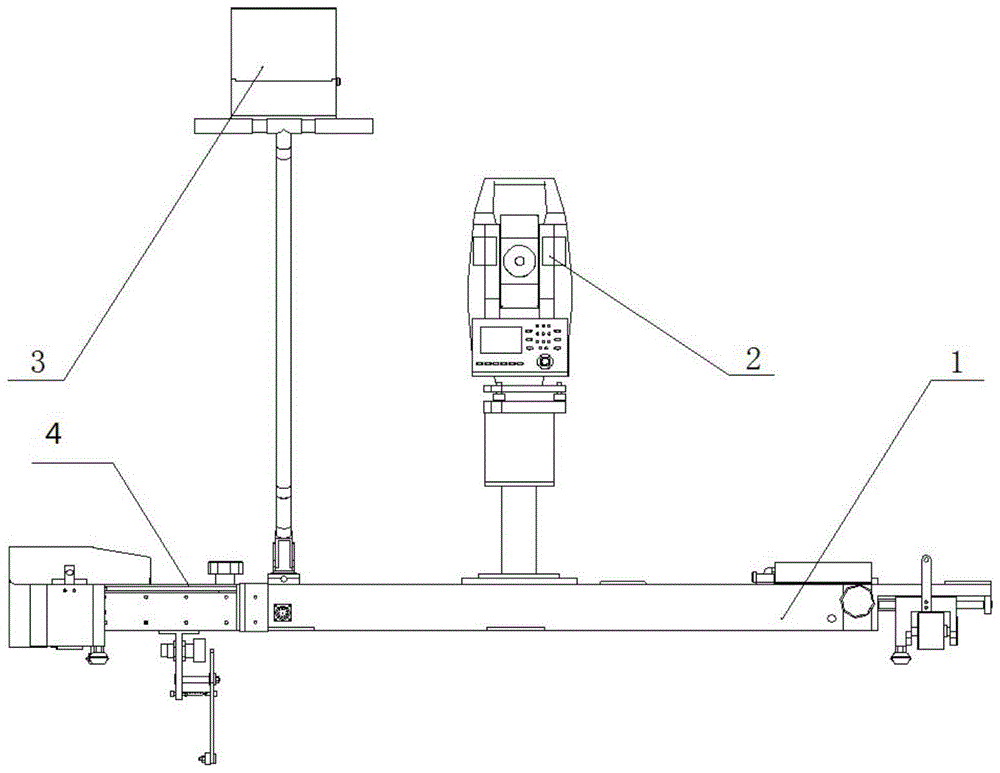

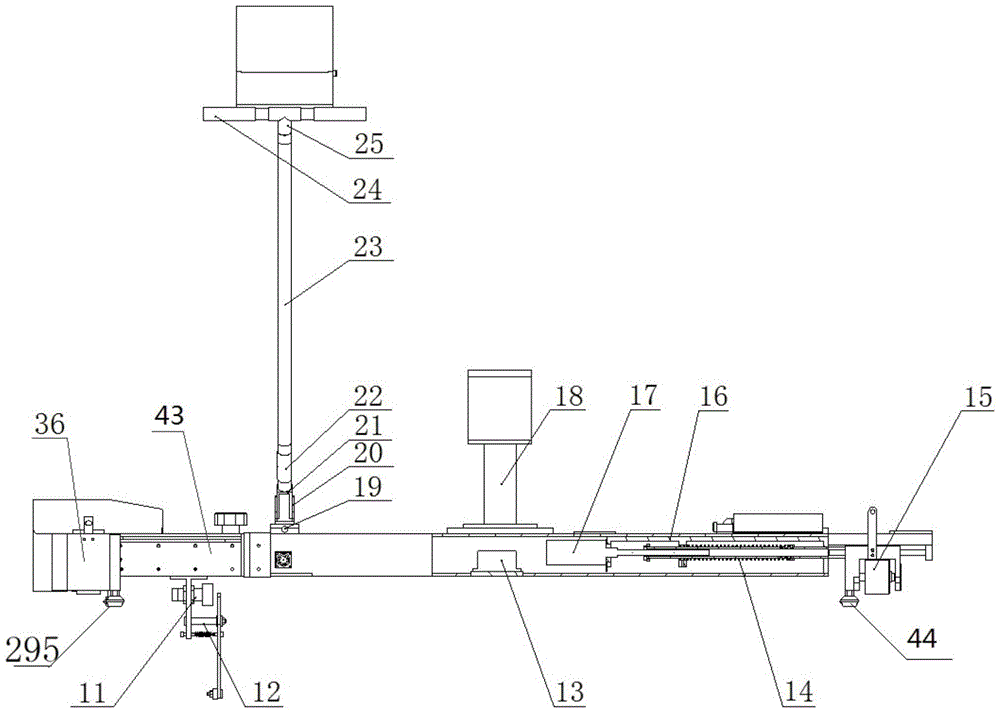

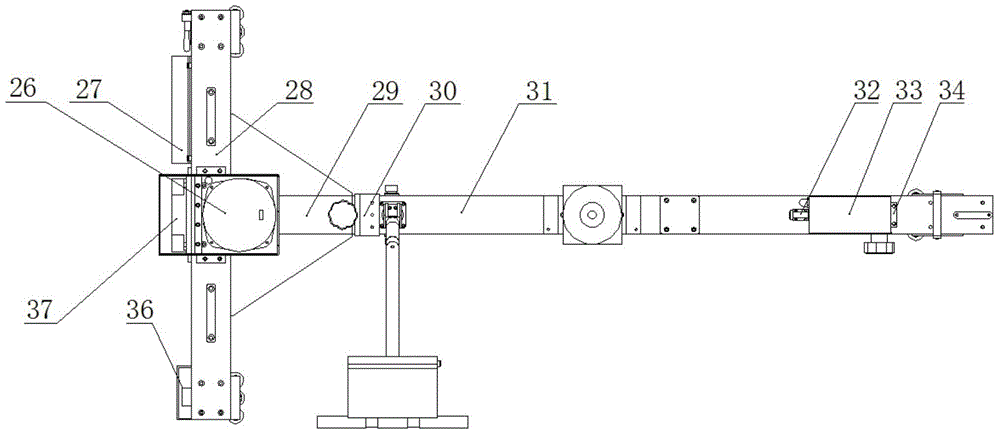

[0025] Such as Figure 1-6Described, a kind of fast fine-tuning track inspection instrument for track geometric parameter measurement, comprises fast fine-tuning trolley, total station 2 and computer 3; Computer 3 adopts CF-19 computer, total station 2 passes communication line or wireless Communication element 27 is connected with computer 3, and the signal collected by data acquisition system 39 is sent to computer 3 through communication line; The wheel beam 1 includes a long beam 31, and the double wheel beam 4 includes a short beam 29 and longitudinal beams 28 arranged symmetrically on both sides with the short beam 29 as the central axis, and the short beam 29 is installed on the long beam through a quick connecting device 30. One end of the crossbeam 31, the quick conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com