Hot-rolling seamless pipe antioxidation disc device

A seamless steel pipe, anti-oxidation technology, applied in the direction of abrasives, metal processing equipment, abrasive jet machine tools, etc., can solve the problems of waste of manpower and material resources, decline of steel pipe yield, coupling failure of couplings, etc., to reduce equipment costs and Improvement of production cost, quality and yield, and avoidance of equipment accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

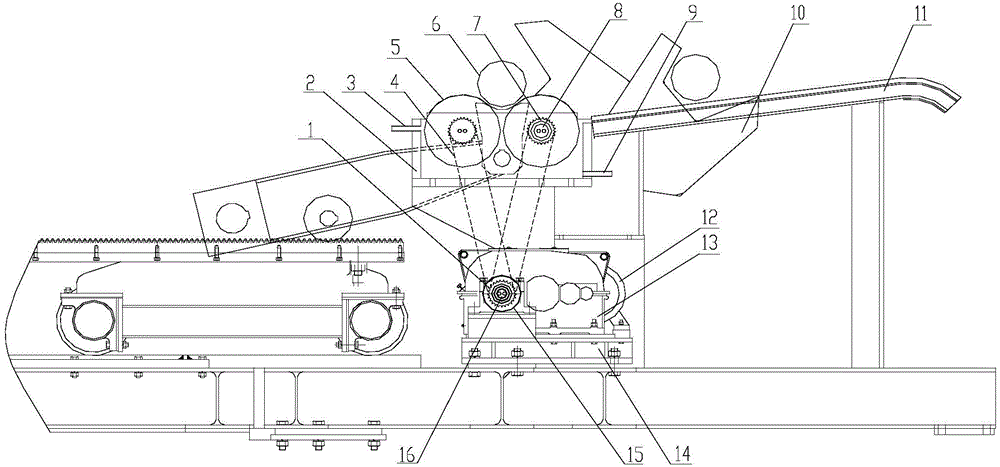

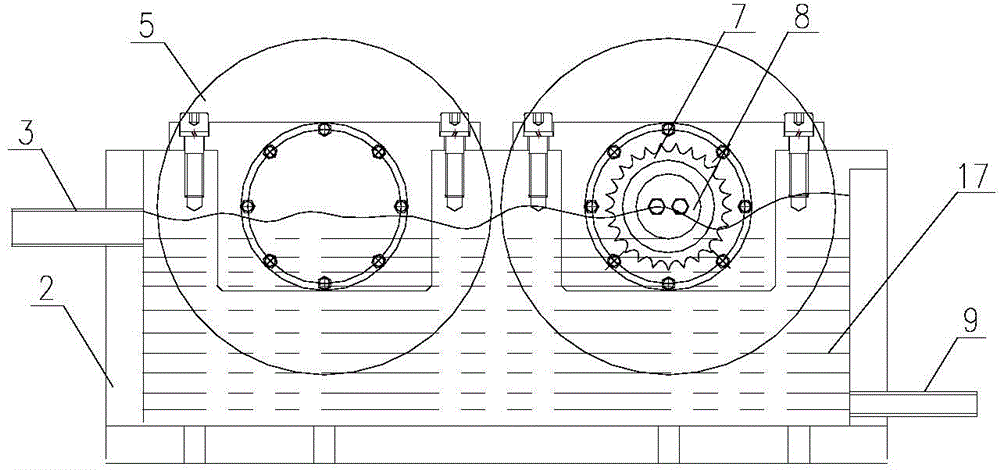

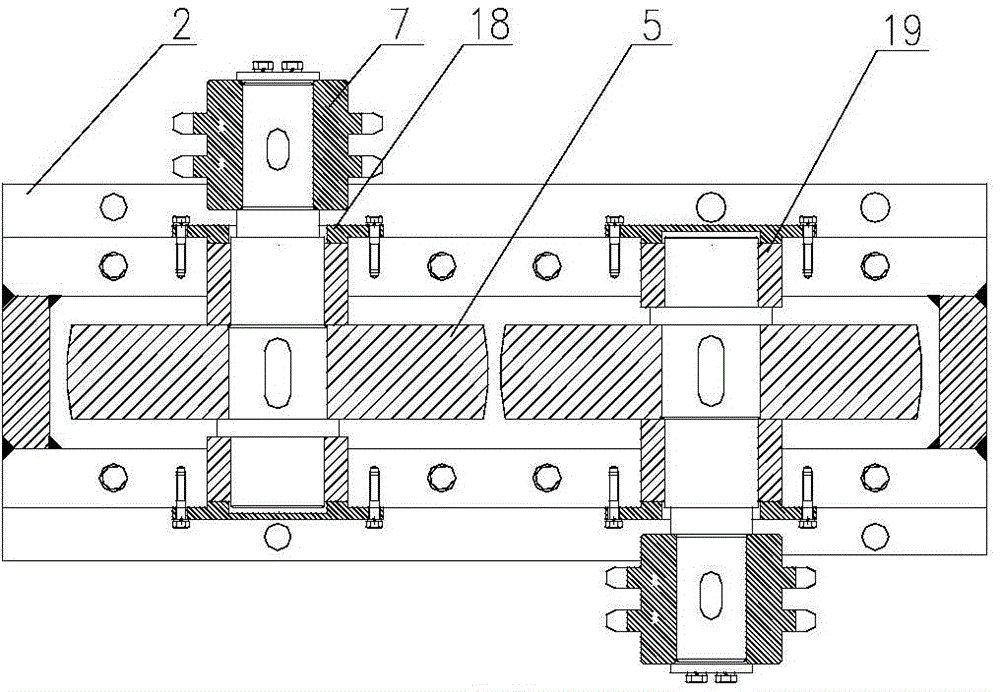

[0023] Depend on Figure 4 It can be seen that the hot-rolled seamless steel pipe anti-oxidation disk device of the present invention is composed of a set of power transmission mechanism and at least 6 groups of disk transmission devices arranged in series, and the 6 groups of disk transmission devices are driven by a set of power transmission mechanism. That is, only the wheel shaft 16 close to the power transmission mechanism is directly connected to the coupling 19 of the power transmission mechanism in the 6 groups of disc transmissions, and the wheel shafts 16 of the remaining 5 groups of disc transmissions are connected together.

[0024] The power transmission mechanism includes a transmission wheel 1 , a motor 12 , a speed reducer 13 , a base 14 and a coupling 20 . The motor 12 and the speed reducer 13 connected thereto are fixed on the base 14 far away from the disk transmission device. The motor 12 is a Y180L-4 variable frequency motor, the shaft coupling 20 is a SW...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com