Forming die of light weight and small size magnesium alloy cooling fan and processing method of inserts therefor

A heat dissipation fan and forming mold technology, which is applied in the field of die-casting molds, can solve the problems of product shortage, deformation, and inability to demould, etc., and achieve the effect of improving forming accuracy and product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

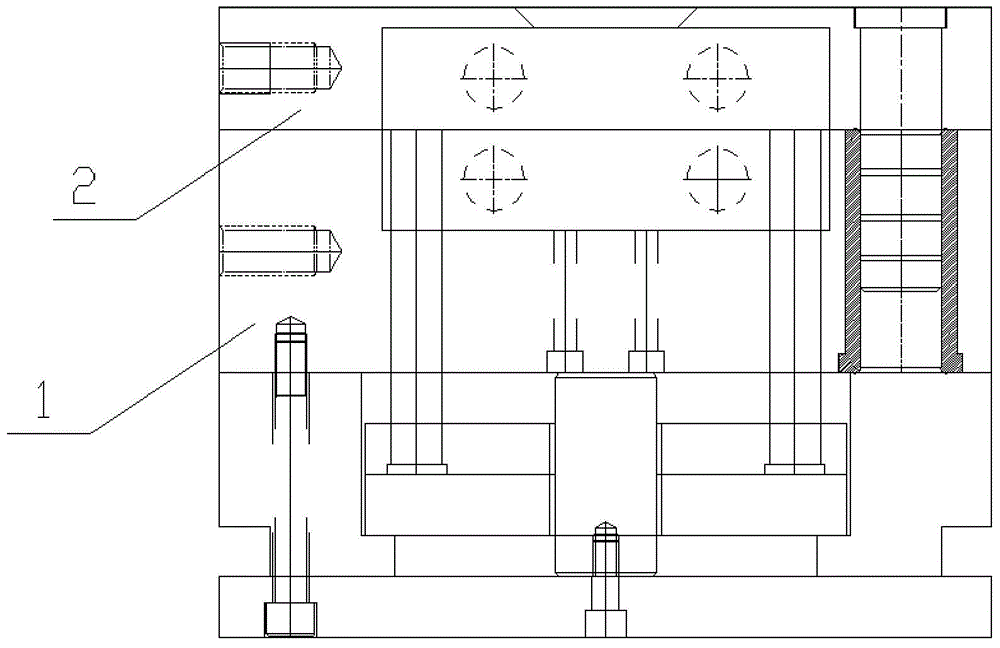

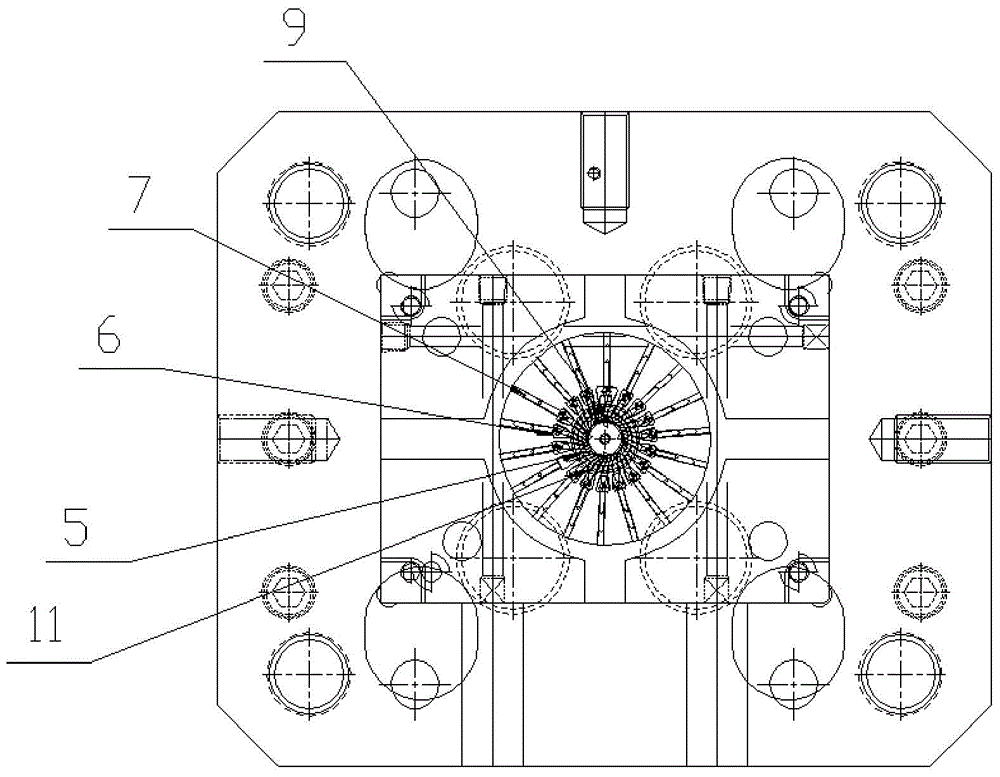

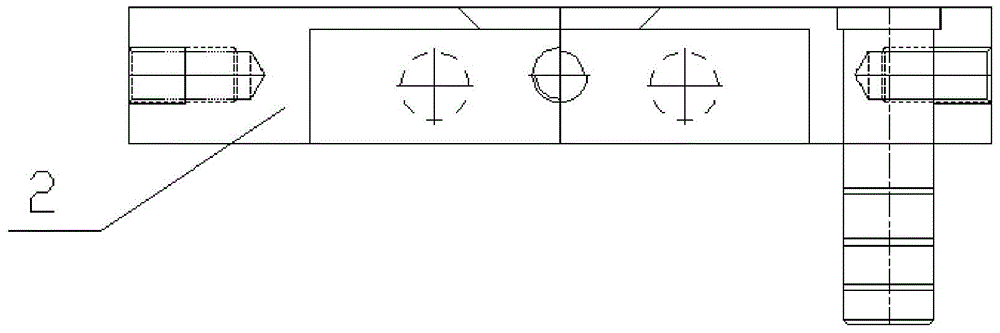

[0031] Embodiment: A molding die for a light and small magnesium alloy heat dissipation fan, comprising a male mold 1 and a female mold 2, wherein: the male mold 1 is provided with a male mold kernel 3, the female mold 2 is provided with a female mold kernel, and the male mold kernel A die-casting cavity is formed between 3 and the female mold core, and a circular thickened inner ring forming space 4 is formed in the male mold core 3, and a number of fan blades are evenly distributed on the outside of the thickened inner ring forming space 4. Corresponding insert grooves, each insert groove is inlaid with inserts 5 respectively, and the two sides of each insert 5 respectively form a fan blade forming structure, and the processing and molding of each fan blade position is realized through the insert 5, which is convenient for mold processing and manufacturing. A thickened inner ring forming space 4 is provided to facilitate the forming and demoulding of fan products.

[0032] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com