A combined leaching and electric repair method for heavy metal-contaminated soil

A technology of contaminated soil and joint remediation, which is applied in the restoration of contaminated soil and other directions, can solve problems such as affecting the remediation effect, and achieve the effect of reducing the amount of use, strengthening the effect of leaching and remediation, and reducing the risk of leaching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

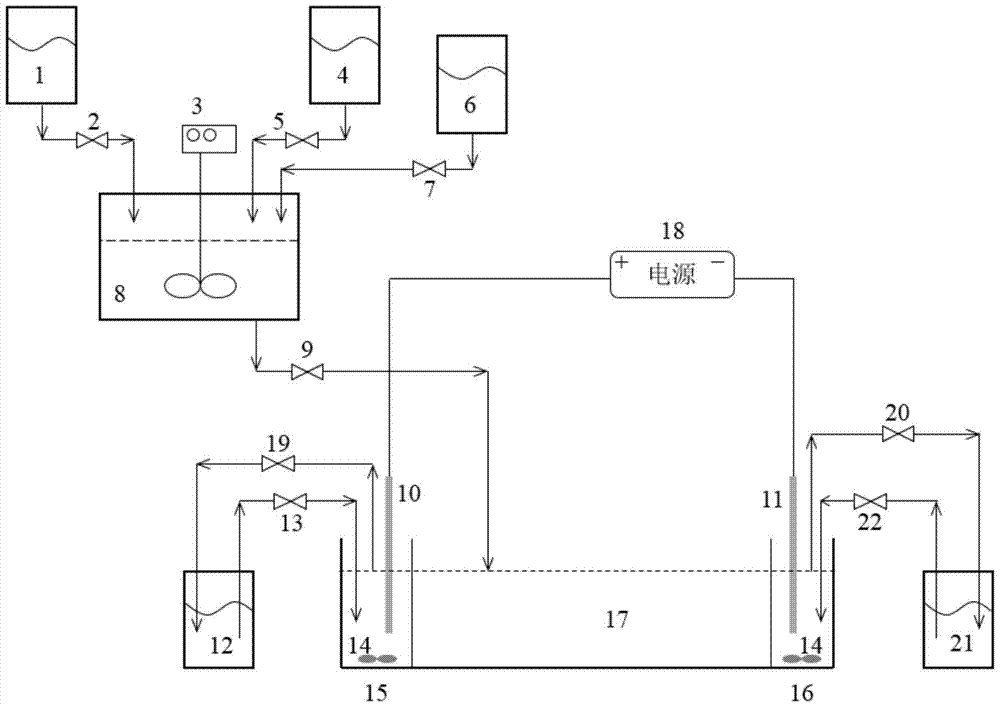

[0036] Depend on figure 1 It can be seen that the electric combined restoration device for washing heavy metal contaminated soil of the present invention comprises the following: a washing system and an electric restoration system;

[0037] The leaching system includes a leaching liquid storage tank 1, a first peristaltic pump 2, a mixer 3, an acid storage tank 4, a second peristaltic pump 5, an alkali storage tank 6, a third peristaltic pump 7 and a contaminated soil storage tank 8 Wherein, eluent storage tank 1, acid storage tank 4, alkali storage tank 6 communicate with contaminated soil storage tank 8 through first peristaltic pump 2, second peristaltic pump 5 and third peristaltic pump 7 respectively; A mixer 3 is arranged inside the tank 8;

[0038]The electrokinetic restoration system includes an anode electrode 10, a cathode electrode 11, an anolyte storage tank 12, a fourth peristaltic pump 13, a stirring device 14, an anode chamber 15, a cathode chamber 16, an elect...

Embodiment 2

[0041] Utilize the device of embodiment 1 to carry out the method for the leaching electric combined repair of heavy metal polluted soil, this method comprises the steps:

[0042] (a) The heavy metal contaminated soil is placed in the contaminated soil storage tank 8, and the acid solution or alkali solution in the acid storage tank 4 or the alkali storage tank 6 is added to the contaminated soil storage tank by the second peristaltic pump 5 or the third peristaltic pump 7 respectively. In the tank 8, the mixer 3 is turned on for continuous stirring, so that the pH of the soil in the contaminated soil storage tank 8 is uniform;

[0043] (b) Add the eluent in the eluent storage tank 1 to the contaminated soil storage tank 8 through the first peristaltic pump 2, keep the mixer 3 for continuous stirring, and fully mix the soil in the contaminated soil storage tank 8 with the eluent Evenly, to ensure that the heavy metal components fully react with the eluent to form complexes and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com