Systems and methods for controlling maximum power point tracking controllers

A technology of controllers and subsystems, applied in the direction of control/regulation systems, instruments, and adjustment of electrical variables, etc., can solve the problem of reverse current flowing through the second string, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

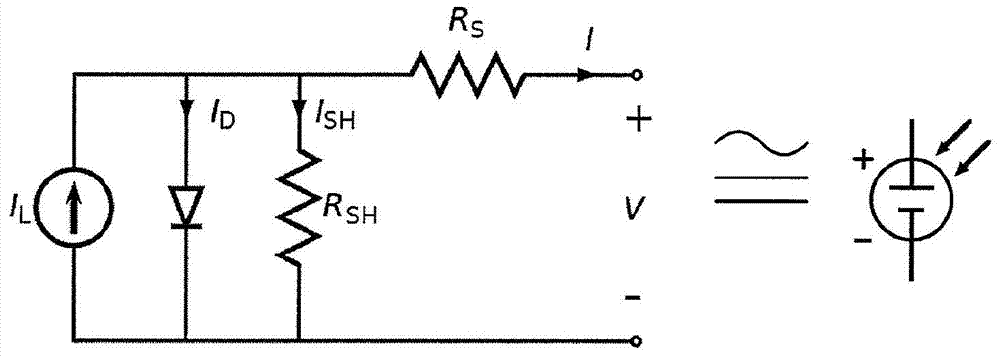

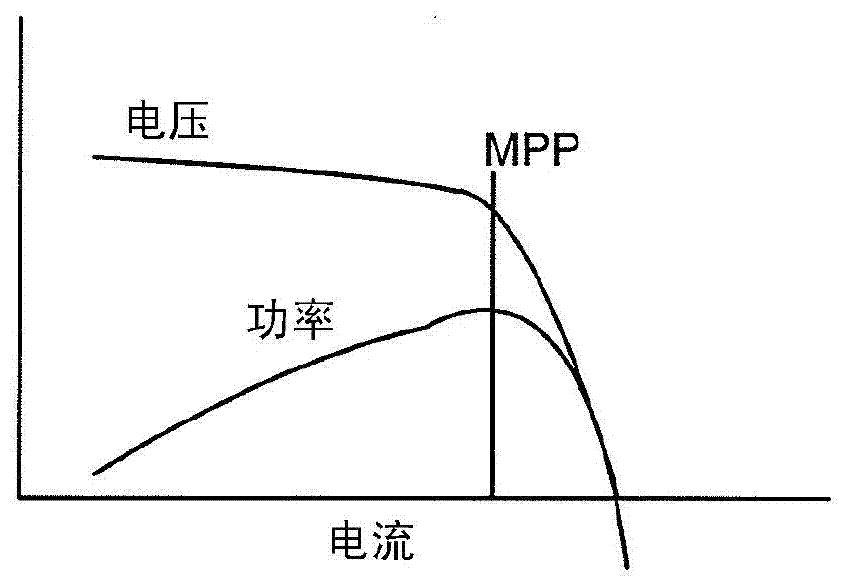

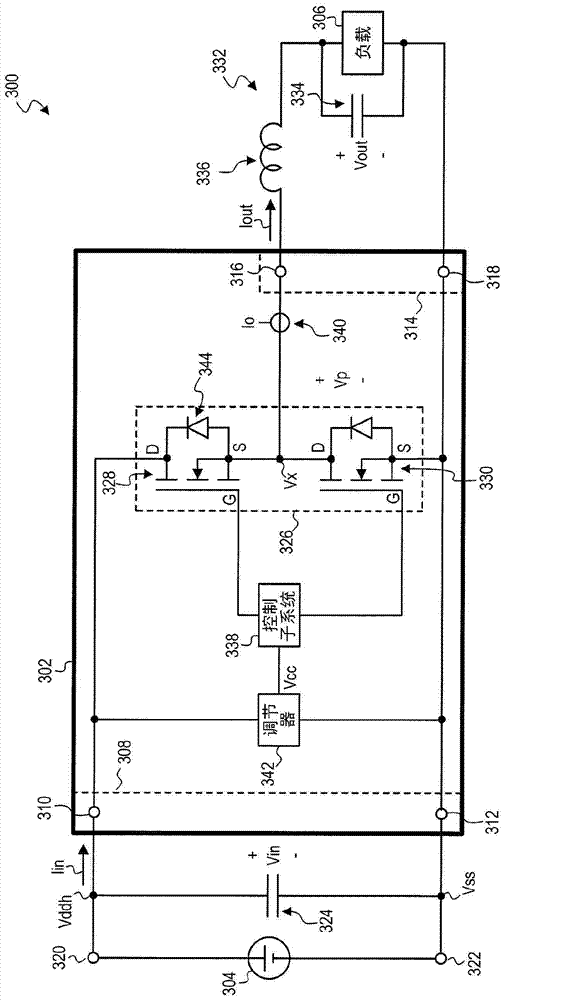

Method used

Image

Examples

Embodiment Construction

[0042] As noted above, an MPPT controller can be used to operate a photovoltaic device at or near its MPP. However, conventional MPPT controllers often interfere with photovoltaic device production line testing. For example, conventional MPPT controllers may block reverse test current and / or overheat if performing EL testing. As another example, the transfer characteristics of a conventional MPPT controller will change during the transient high voltage test, thereby interfering with the determination of Voc, Isc and Pmp. Therefore, photovoltaic devices typically cannot be electrically coupled to conventional MPPT controllers during device production line testing.

[0043]This limitation of conventional MPPT controllers is a particularly serious disadvantage in applications where multiple MPPT controllers are packaged together with multiple photovoltaic devices. In these applications, MPPT controllers typically provide part of the interconnection between photovoltaic devices....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com